Automation for precise dispensing and gluing processes

Use Case Dispensing

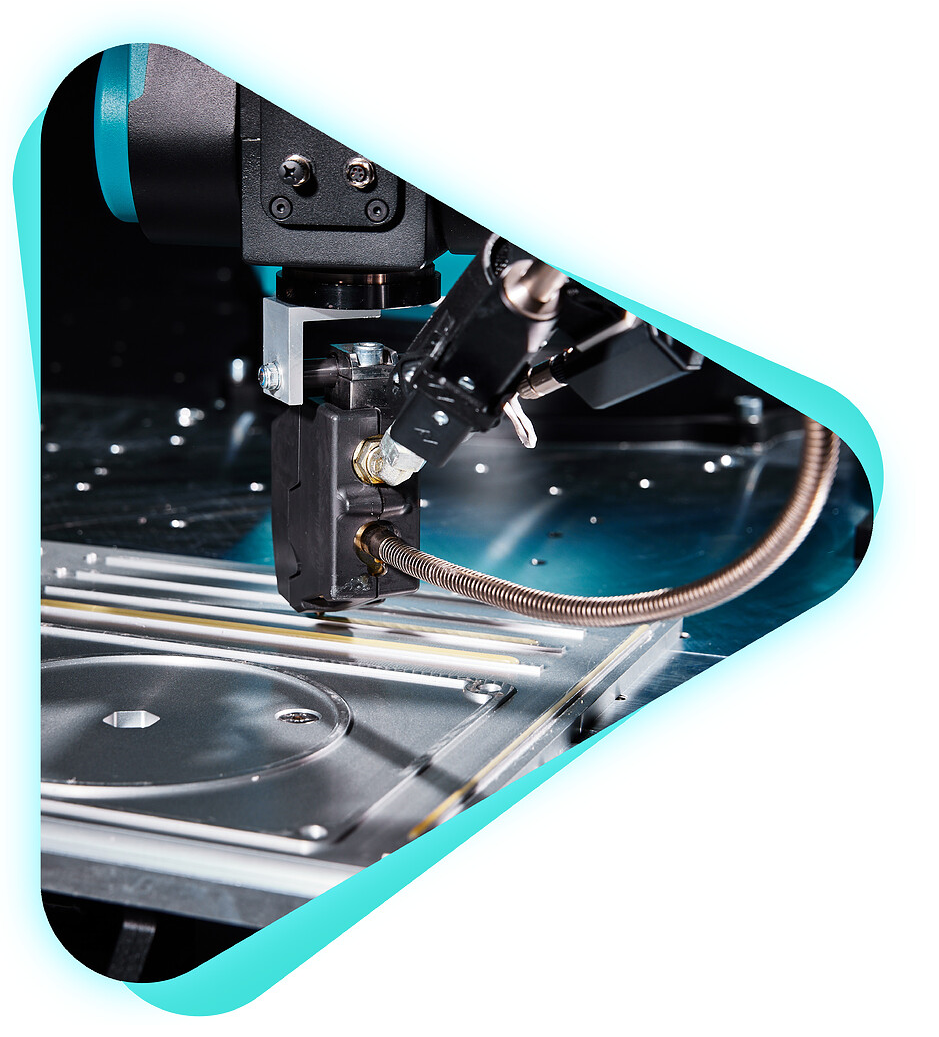

Experience the precision and flexibility of our industrial robots in your dispensing and gluing applications.

Overcome your bonding and dispensing challenges

Thanks to the high degree of freedom of movement in three-dimensional space, our intelligent industrial robots and automation solutions provide you with the best results when it comes to precisely dispensing and applying adhesives or other materials.

Benefit from the high adaptability to uneven geometries and the simple programming of complex paths. Improve your results even further with versatile tools and integrated component inspection.

Precision and adaptability

Its joints and rotation options allow our six-axis robot to perform complex dispensing movements. Thanks to its high freedom of movement, HORST can be easily adapted to different shapes and even uneven or curved geometries. Because the dispensing tip can be tilted in different angles and directions, our automation solutions are suitable for almost any dispensing media requirement.

Complete the entire process quickly and easily

Your intelligent industrial robot can easily be equipped with different end effectors. This means that, in addition to dosing, the handling or testing of the component can also be carried out at the same time. You also benefit from the fact that your HORST robot system can be seamlessly integrated into your environment.

User-friendly programming

Create harmonious and smooth movements using the horstOS software feature for creating complex paths. Precisely control output signals with our user-friendly programming software to maximize the efficiency of your dispensing and gluing processes.

Why HORST:

Our intelligent industrial robots for your best bonding and dispensing results

Rely on us for an efficient and future-oriented automation experience.

The latest technologies at all levels

Our in-house developed industrial robots have innovative, patented robot gears. This gives you the best return on investment on the market: your new HORST can pay for itself in just three months.

Comprehensive networking and communication of the systems

Thanks to extensive digital services, the use of IIoT, a SIM card integrated into the robot system and access to all common industrial interfaces, you have full connectivity to existing systems and processes.

Use of artificial intelligence

We use the full range of artificial intelligence and machine learning in the development of our products and software. In this way, we not only improve the results of your applications, but also continue to simplify the setup of automation. In close cooperation with you, we are always working to exploit the benefits of these new technologies for your purposes.

What our satisfied customers say about HORST

By automating our gluing application with the Digital Robot HORST, we have efficiently optimized our processes and are now able to produce autonomously. The user-friendly graphical user interface enabled us to program and commission the application quickly and easily.

Andreas Beck / Design technician for test equipment and fixture construction at the Villingen-Schwenningen plant

HORST - the industrial robot for gluing and dispensing

Put together your own intelligent automation solution with just a few clicks

- Which robot will help you best?

- Which software features give you a competitive edge?

- How do you secure the best lifecycle costs with additional services?

Further resources on the topic

Learn more about the automation of gluing and dispensing applications.

Your direct contact for questions about gluing and dispensing

Do you have any further questions about automation solutions for gluing and/or dispensing processes? Or do you already have a specific application in mind that requires precise, fast and user-friendly dispensing applications? Please do not hesitate to contact us. We look forward to discussing your individual needs and finding the best solution together with you!

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de