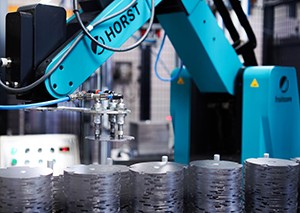

HORST1000 is the intelligent all-rounder among industrial robots – powerful, flexible, and developed for a wide range of demanding applications.

With its high payload of 8 kg and maximum mobility, it is ideal for machine loading, small parts handling, and palletizing tasks.

Select an option below:

- What you receive

- Technical Data

- Downloads

- Bilder

Technical data that impresses: performance values, precision, and robustness that you can rely on in industrial applications.

Robot

- 6 axes

- Reach: 1018 mm

- Load capacity: 8 kg

- Repeatability: ± 0.05 mm

- Protection class: IP54

- Weight: 70 kg

- Warranty: 6-year warranty on motors and gearboxes

Control

- Compact unit (313 × 174 × 446 mm)

- Protection class IP20

- Weight: 10 kg

- Power supply: 230 VAC / 50–60 Hz, typical: 250–500 W

- 20 inputs | 18 outputs

- TCP/IP, Ethernet, XML-RPC, Profinet, Modbus

Panel

- 13.3" touchscreen (2560 × 1600 – 2.5K)

- Protection class: IP54

- 2 USB 3.0 ports, 5 m cable

- Ambidextrous operation with adjustable handles & consent button

Technical data that impresses: performance values, precision, and speed that you can rely on in industrial applications.

You receive a robot, controller, panel, and software that are perfectly coordinated, ready for immediate use, and 100% made in Germany.

- HORST1000 industrial robot

- Compact Control controller

- Ergonomic panel

- Central automation operating system for operation, programming, and process control, +AI Copilot

Downloads

Find out more about the intelligent industrial robot HORST1000.

Configure your HORST1000 now.

Just a few steps to your customized industrial robot..

Put together your HORST1000 according to your requirements.

Select components, accessories, software packages, and interfaces, and immediately receive a transparent overview of your customized configuration.

Simple. Fast. Transparent. This is how you design your automation with HORST.

HORST1000 does not come alone.

Four models. Countless possibilities

Discover the entire HORST family – from compact models for confined workspaces to powerful variants for long ranges and high load capacities.

You will find the right HORST for every application.

HORST1000

Reach

1018 mm

Load capacity

8 kg

Repeat accuracy

+/- 0,05 mm

Weight

70 kg

One for many tasks.

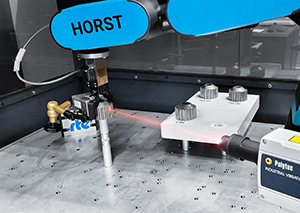

Typical applications of the HORST1000.

HORST1000 shows its strengths wherever power, agility, and precision are required.

Whether in machine loading, small parts handling, or palletizing tasks, thanks to AI-supported motion optimization, it can also handle large magazines, trays, and pallets with ease.

Learn more about the suitable applications and discover how HORST1000 can help increase your productivity.

Ready for your new colleague HORST?

Talk to our experts.

Our robotics experts will assist you with questions regarding the feasibility, planning, and setup of your application—personally, practically, and on an equal footing.

Together, we will find the right solution for your automation needs.

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de