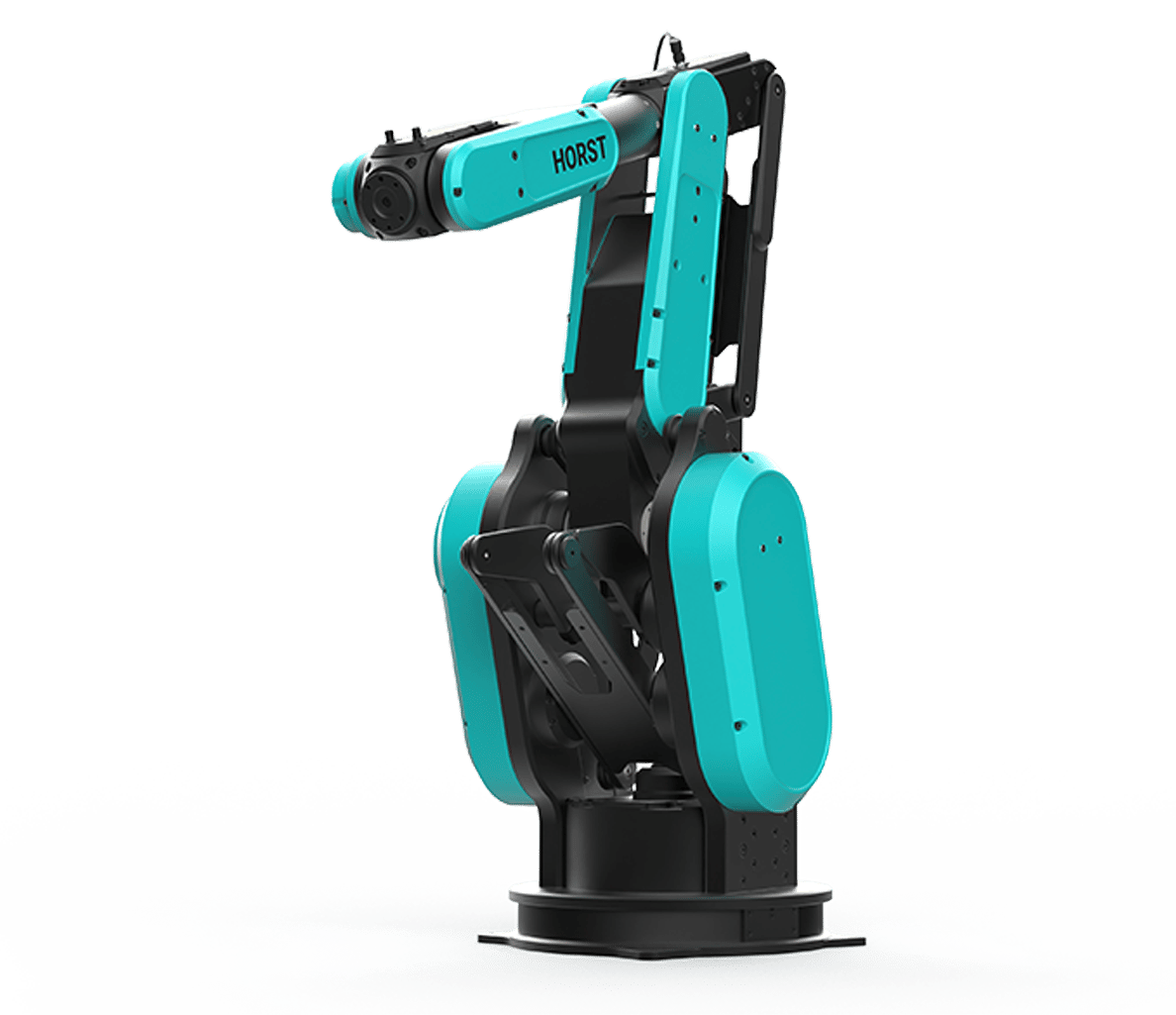

HORST1000 G2: When only maximum performance at minimum cost counts for you

The intelligent HORST1000 G2 industrial robot is the durable and reliable solution for automating your production. It is hard-wearing and robust, which is important in harsh industrial environments. The user-friendly and AI-supported software allows you to program demanding tasks without prior robot knowledge.

What HORST1000 G2 does for you

Maximum performance under all production conditions

With a load capacity of up to 16 kg, the HORST1000 G2 moves heavy tools and components effortlessly. With a reach of 1141 mm, it reaches far into machines. Its robust design saves you expensive downtime, especially in harsh CNC environments. This robot is perfect for demanding tasks in parts handling or machine loading.

Lowest service life costs on the market thanks to patented drive technology

HORST1000 G2 offers gearboxes that are four times more durable than standard market solutions and a 6-year warranty on the drive train. This makes it a future-proof solution that reduces your operating costs and protects your budget.

Adaptable automation through seamless integration

HORST1000 G2 adapts ideally to your requirements so that you remain flexible and can react immediately to market changes or customer requests. Use user-specific software interfaces and integrate your robot seamlessly into existing processes or our ready-made automation modules.

HORST1000 G2 Specifications,Productdetails

| Details | Specifications |

|---|---|

Number of axes |

6 |

Maximum load capacity |

16 kg |

Maximum reach |

1141 mm |

Repeatability |

+/- 0,05 mm |

Protection class of hand axes 4, 5 & 6 |

IP65 |

Protection class of the rest of the robot |

IP54 |

Weight |

103 kg |

Power supply |

230 VAC, 50-60 Hz, Typically: 350 W |

Ambient temperatur |

5-40 °C |

Warranty |

6 years on engines and gearboxes |

We use the test cell for technological feasibility analyses and innovations in product development and are thrilled. The Solution Kit can be put into operation, programmed and operated quickly and easily without any special prior knowledge.

Robert Meißner / Senior Expert Manufacturing Technologies, Research & Development at fischer group

With HORST, we are very well positioned in our test lab. The compact footprint is very convenient and the usability of the robot is a great advantage, especially for the complex test setups.

Frank Reinauer / Senior Director Division Implants at Karl Leibinger Medizintechnik GmbH & Co. KG

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

The high quality demands placed on our products require first-class quality assurance. By using the HORST industrial robot, we have not only created the best testing conditions, but also significantly increased product quality. The robot has relieved our employees of monotonous tasks as well as led to an increase in productivity and a high level of satisfaction among our customers.

Lorenz Geyer / Managing Director Eugen Geyer GmbH

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

HORST takes over typical pick & place tasks for us during a hydraulic test and enables a fully automated testing process. As a result, we achieve a significantly higher output and increase our productivity. We were also convinced by the easy operation of the industrial robot, the good price and the comprehensive support from fruitcore.

Thomas Sehling / Operational Excellence Manager at WEBER-HYDRAULIK GmbH

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

HORST is inexpensive to purchase, requires little space, can be used flexibly and is easy to handle thanks to intuitive operation with the horstFX robot software.

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Above all, the flexible applicability of HORST convinced us. In addition, the price-performance ratio fits and we simply have a team at our disposal that flexibly implements the individual task with us.

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

The great advantage of HORST and the control system is that it can be used completely flexibly in an SME. I don't need highly trained technical personnel who are specialized in the application with or programming of robots, but can also train the normal machine operator on HORST.

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

We were able to initialize HORST within a very short time and thus get started directly with program applications. The operating panel is very pleasant to use.

Siegmar von Detten / Computer science teacher at Zeppelin Gewerbeschule Konstanz

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Beat Glauser / CTO MBV AG

Configure now

Put together your own integrated automation solution based on HORST1000 G2 with just a few clicks.

- HORST1000 G2 or another robot system: check which model suits you best.

- Gain an additional competitive advantage with software features.

- Ensure the best lifecycle costs with our unique service.

Downloads

Find out more about the intelligent industrial robot HORST1000 G2.

HORST1500 is not alone: more industrial robots from fruitcore robotics

Contact us for more details about HORST1000 G2

Would you like to know how you can use HORST1000 G2 in your production? Our robotics experts will be happy to help you with questions about the feasibility and setup of your project.

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de

%20Kopie.webp)