Why HORST

Discover the future of industrial automation with us. Together we can make your production more efficient, faster and smarter.

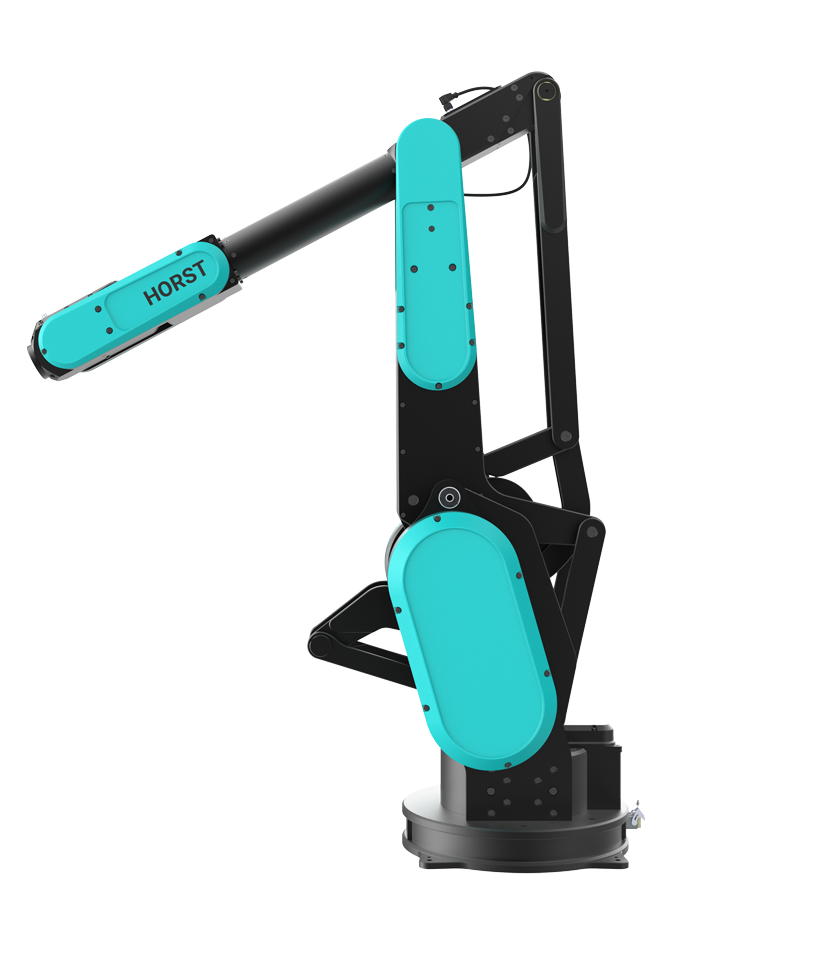

Welcome to the world of HORST, our intelligent high-tech industrial robot

Imagine a world where industrial processes are optimized and simplified through the use of intelligent robotic systems. A world where the latest technologies, artificial intelligence and machine learning raise your productivity and efficiency to a level you never thought possible before. The Digital Robot HORST offers you exactly that and much more!

Rely on the latest technology and artificial intelligence with HORST

Achieve the highest quality and productivity with a highly optimized robot system and improve your processes with our passion for innovation and development.

Highly Optimized Robotic Technology

HORST stands for "Highly Optimized Robotic Systems Technology". Designed and manufactured in Germany, our robotic gearboxes are optimized through machine learning and offer a unique combination of quality, efficiency and technological advancement.

Increased performance

Our continuous development using advanced technology has significantly increased the performance of the HORST1000 over the HORST900 model - including an impressive 60 percent increase in payload.

Experience new industry standards

With the targeted use of advanced technologies such as machine learning or artificial intelligence, we are setting new standards in industrial robotics. With us, you can rewrite the history of automation.

Support through AI

The future of robot programming lies in AI. Imagine how easy programming and implementing your applications could become if they are supported by an AI co-pilot.

Seamless integration and incorporation

With our Digital Robots, you avoid lengthy setup processes and lead times. Our goal is to get you up and running as quickly as possible.

Easy integration

HORST uses state-of-the-art technologies in robotics and offers seamless integration with your existing systems, avoiding complex setup processes and saving costs.

Versatile compatibility

Our robot hardware is equipped with all industry-standard interfaces and connects easily with your systems.

User-friendly software

Our proprietary horstFX software is designed to be user-friendly and enables easy automation even without prior programming knowledge.

Efficient programming

With horstFX, important standard applications can be programmed graphically in just 30 minutes - without any experience in textual coding for robots. This makes implementation easier and more cost-efficient.

Support for beginners and experts

Whether you are a beginner or an expert, horstFX offers a variety of templates and pre-trained programs for easy automation. It also allows you to easily switch between simplified graphical and more complex textual programming.

Pre-assembled complete solutions

We offer pre-assembled solution kits with a complete safety concept. After on-site integration, these can be used immediately - for tasks such as pick & place or parts separation.

Smart connectivity for optimized processes

Get additional benefits with digital services for HORST such as our own IIoT platform and an integrated SIM card.

Smart connectivity

With HORST, you benefit from our proprietary IIoT platform horstCOSMOS, which enables connected, data-driven automation.

Predictive Maintenance

By analyzing the telemetry data of your robotic systems, you can detect problems before they cause failures. This extends the life of your machines and equipment and reduces unplanned downtime and costs.

Real-time monitoring

Thanks to HORST's smart connectivity, you can monitor in real time whether your processes are running as desired and quickly adjust them if necessary.

Connected regardless of location

Our digital robots are equipped with SIM cards and the necessary data volume. This keeps your HORST connected to other devices and systems regardless of location and enables efficient analysis of running processes, even when access to your corporate network is not possible.

Automating with HORST is solving challenges

Learn more about our intelligent automation solutions for your applications.

Assembly

- HORST achieves high speeds and is enormously repeatable (±0.05 mm). This makes HORST ideal for assembly processes that require short cycle times and high precision.

- HORST can be used in hazardous or chemical-laden environments, reducing the risk to assembly workers. In addition, it can be equipped with various grippers, tools or sensors to achieve the optimal flow of the process.

- HORST uses the latest technologies such as Artificial Intelligence and Machine Learning and provides full connectivity into existing systems and processes.

Machine feeding

- In a competetive market, quality is critical. HORST enables high accuracy in picking and placing workpieces, which improves product quality and reduces scrap.

- The safety of employees is of paramount importance. HORST can be used for hazardous or unhealthy tasks, reducing the risk of workplace accidents.

- In today's fast-paced production world, felxibility is crucial. HORST can be quickly adapted to changing tasks and production scenarios.

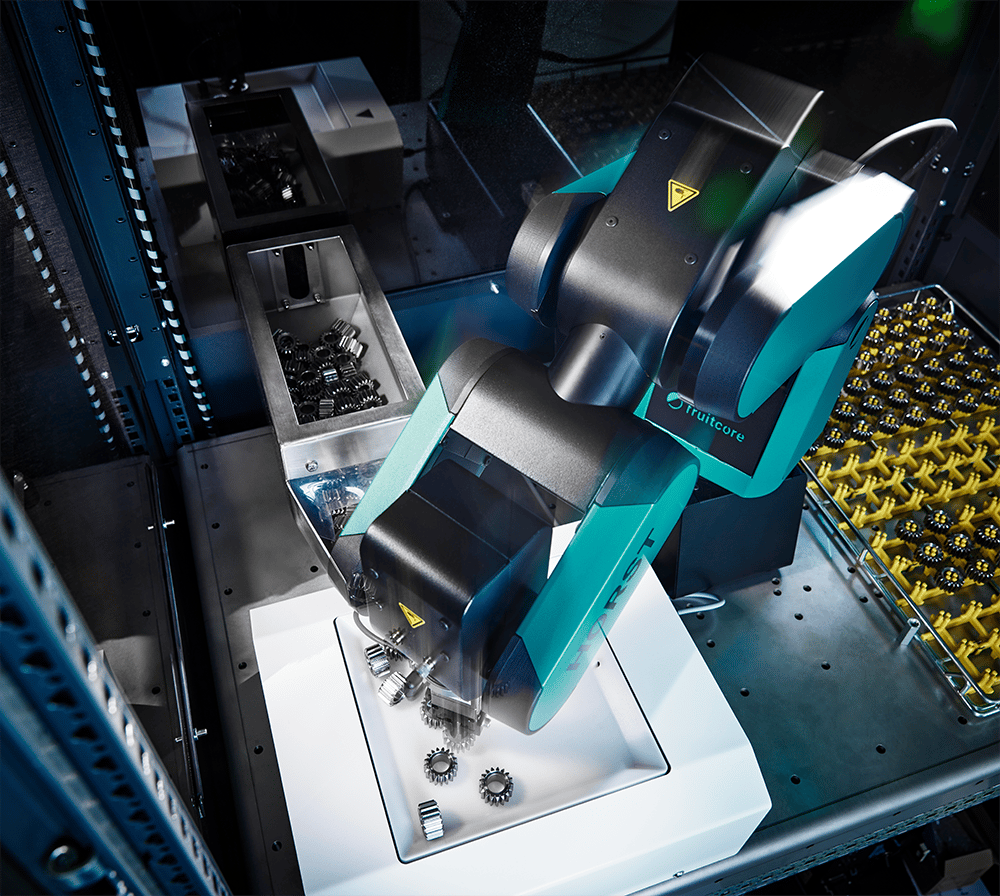

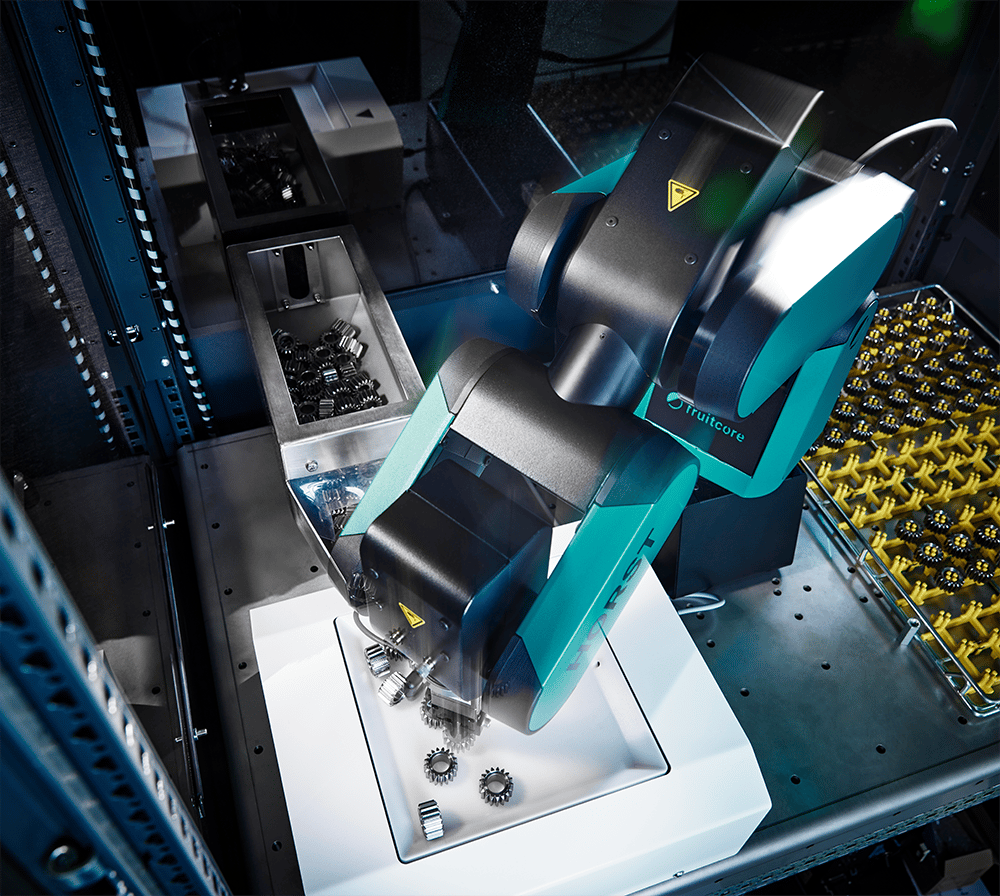

Part Separation

- Accuracy in sorting parts is crucial for the quality of the final product. HORST offers an extremely high repeatability of ±0.05mm, which enables precise separation.

- Manual processes can be time-consuming and inefficient. HORST enables faster and continuous feeding of bulk material without the need for constant staff intervention.

- In a constantly changing market, the ability to adapt quickly is crucial. HORST is designed to meet a wide range of requirements.

Quality Inspection

- Consistency in quality inspection is critical to the reliability of the end product. HORST provides precisely defined movements and minimizes external influences, enabling precise and consistent quality inspection.

- Being able to detect quality defects in complex surfaces is crucial for many industries. HORST can be equipped with a camera and offers flexible 6 axis kinematics to inspect complex surfaces from different angles.

- Changing over to new processes or applications quickly and cost-effectively is essential for a company's competetiveness. HORST enables simple adaptations, even for the smallest series.

Learn more

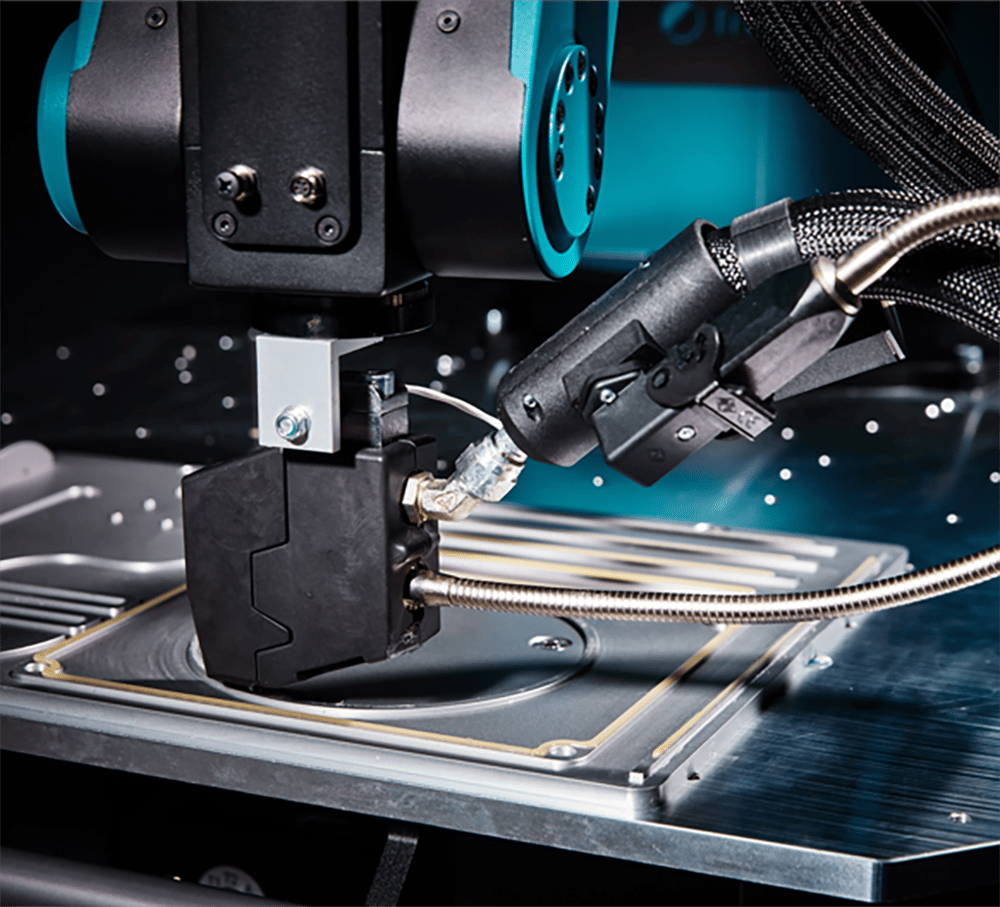

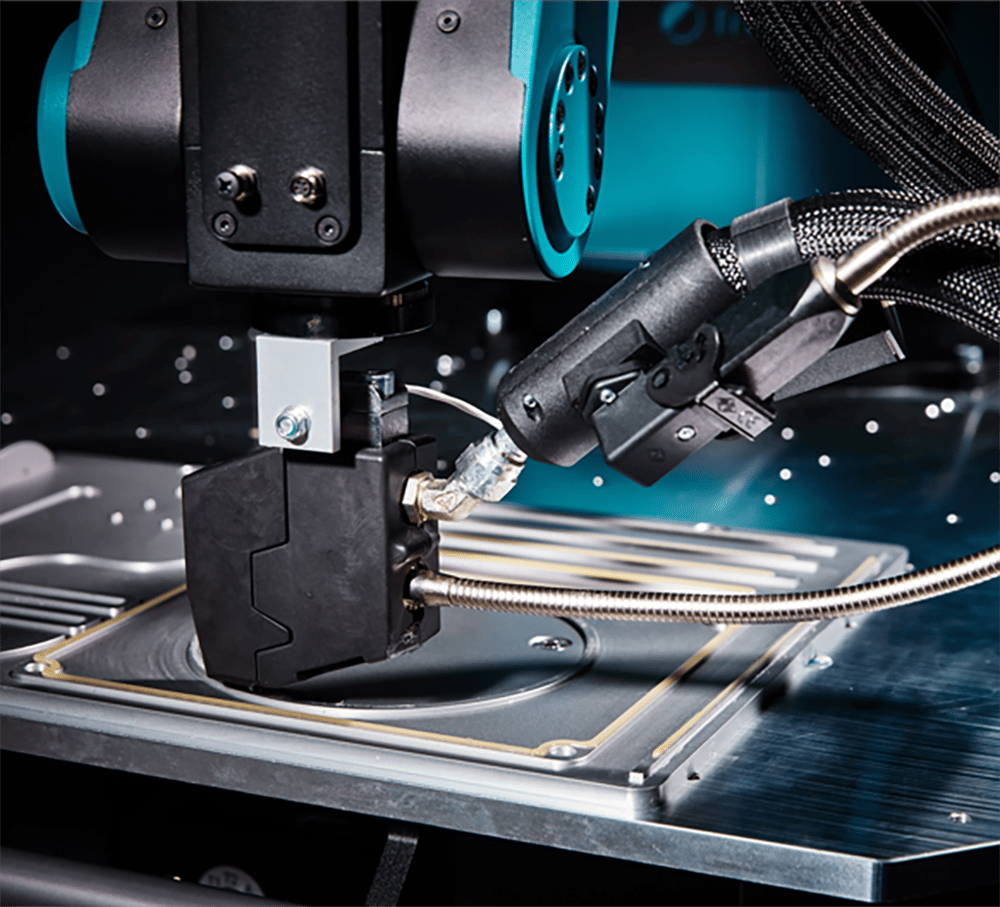

Dispensing and Bonding

- The HORST 6-axis industrial robot enables complex dispensing movements and adapts effortlessly to uneven or curved geometries. This enables precise dispensing and application of adhesives or other substances.

- HORST can easily be equipped with different end effectors to handle or inspect the component in addition to dispensing. It can be seamlessly integrated into your entire production environment.

- With the horstFX software feature for creating complex paths and the use of artificial intelligence and machine learning, our Digital Robot offers maximum efficiency in your dispensing and gluing processes.

Learn more

Assembly

- HORST achieves high speeds and is enormously repeatable (±0.05 mm). This makes HORST ideal for assembly processes that require short cycle times and high precision.

- HORST can be used in hazardous or chemical-laden environments, reducing the risk to assembly workers. In addition, it can be equipped with various grippers, tools or sensors to achieve the optimal flow of the process.

- HORST uses the latest technologies such as Artificial Intelligence and Machine Learning and provides full connectivity into existing systems and processes.

Machine feeding

- In a competetive market, quality is critical. HORST enables high accuracy in picking and placing workpieces, which improves product quality and reduces scrap.

- The safety of employees is of paramount importance. HORST can be used for hazardous or unhealthy tasks, reducing the risk of workplace accidents.

- In today's fast-paced production world, felxibility is crucial. HORST can be quickly adapted to changing tasks and production scenarios.

Part Separation

- Accuracy in sorting parts is crucial for the quality of the final product. HORST offers an extremely high repeatability of ±0.05mm, which enables precise separation.

- Manual processes can be time-consuming and inefficient. HORST enables faster and continuous feeding of bulk material without the need for constant staff intervention.

- In a constantly changing market, the ability to adapt quickly is crucial. HORST is designed to meet a wide range of requirements.

Quality Inspection

- Consistency in quality inspection is critical to the reliability of the end product. HORST provides precisely defined movements and minimizes external influences, enabling precise and consistent quality inspection.

- Being able to detect quality defects in complex surfaces is crucial for many industries. HORST can be equipped with a camera and offers flexible 6 axis kinematics to inspect complex surfaces from different angles.

- Changing over to new processes or applications quickly and cost-effectively is essential for a company's competetiveness. HORST enables simple adaptations, even for the smallest series.

Learn more

Dispensing and Bonding

- The HORST 6-axis industrial robot enables complex dispensing movements and adapts effortlessly to uneven or curved geometries. This enables precise dispensing and application of adhesives or other substances.

- HORST can easily be equipped with different end effectors to handle or inspect the component in addition to dispensing. It can be seamlessly integrated into your entire production environment.

- With the horstFX software feature for creating complex paths and the use of artificial intelligence and machine learning, our Digital Robot offers maximum efficiency in your dispensing and gluing processes.

Learn more

Assembly

- HORST achieves high speeds and is enormously repeatable (±0.05 mm). This makes HORST ideal for assembly processes that require short cycle times and high precision.

- HORST can be used in hazardous or chemical-laden environments, reducing the risk to assembly workers. In addition, it can be equipped with various grippers, tools or sensors to achieve the optimal flow of the process.

- HORST uses the latest technologies such as Artificial Intelligence and Machine Learning and provides full connectivity into existing systems and processes.

Your contact at fruitcore robotics

Would you like to get to know HORST even better and learn how our Digital Robot can also solve your challenges? Contact our robotics experts today and revolutionize your processes with HORST!

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de