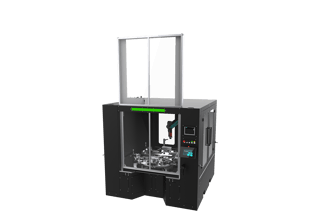

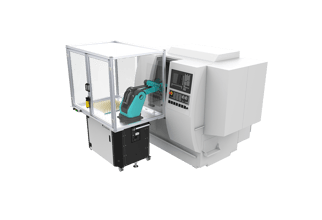

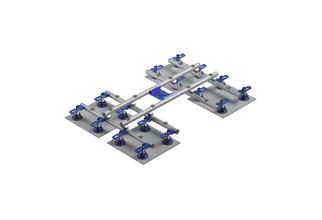

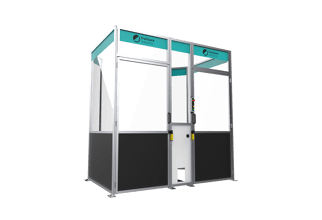

Automatic forming press

Automatic forming press

With this turnkey solution, you can automate your forming processes safely and reliably in the shortest possible time.

Manufacturer

Dreisbach & Jungmann GmbH & Co. KG

Discover the versatile world of our ecosystem for HORST and dozens of compatible components, component kits, solution kits and turn key solutions as the basis for your efficient automation with intelligent digital robots.

2.webp?width=410&height=220&name=Solution%20Kit%20Pick%20&%20Place%20(weiss)2.webp)

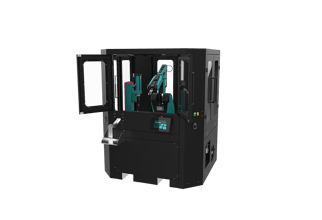

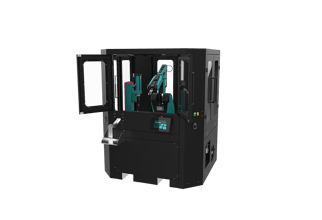

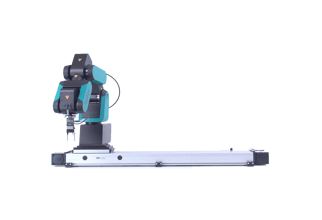

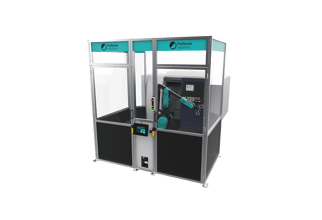

Robot cell with operating console and safety lock

Robot cell with operating console and safety lock.

2.webp?width=410&height=220&name=MRB%20S%2cM%2cL%20mit%20Schutzraum(weiss)2.webp)

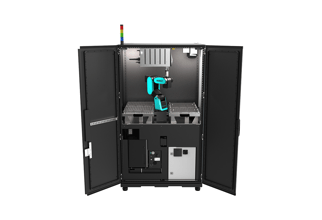

The mobile robot base with safety fence, safety lock and operating console offers flexibility and simplicity when implementing automation projects with HORST.

%202.webp?width=410&height=220&name=Mobile%20Roboterbasis%20MRB%20S%2cM%2cL(weiss)%202.webp)

Flexible working platform for HORST with chassis for easy positioning of the application.

Technical data:

Quickstart guide:

https://cdn.sick.com/media/docs/9/89/789/quickstart_ploc2d_en_im0085789.pdf

Electric suction pad with integrated vacuum generation

https://www.schmalz.com/de-de/vakuumtechnik-fuer-die-automation/vakuum-komponenten/vakuum-erzeuger/vakuum-erzeuger-end-of-arm/handling-sets-ecbpmi-308307/10.03.01.00677/

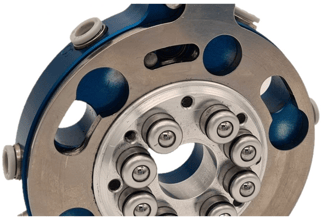

The VSpin robot spindle offers the option of monitoring and storing all relevant data from the deburring process. Complete process monitoring with the VPort is also available as an option.

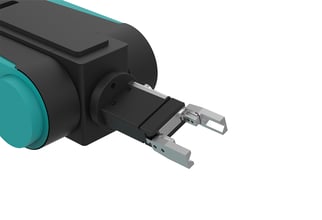

The flexible 2-finger robot gripper RG2 with a large stroke can be used for a wide variety of part sizes and shapes.

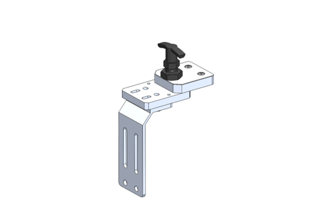

The TR110 Lock security interlock uses RFID technology and mechanical reliability for maximum security, including escape release and illuminated buttons.

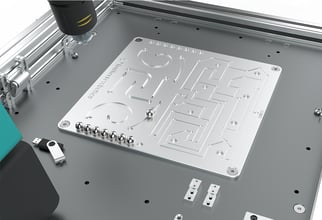

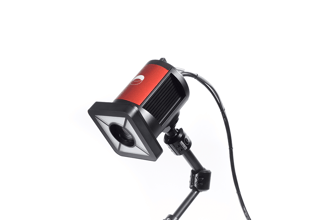

INSPEKTO S70 is a ready-to-use complete system for industrial visual inspections with autonomous AI technology. It is easy to customize and requires no image processing expertise.

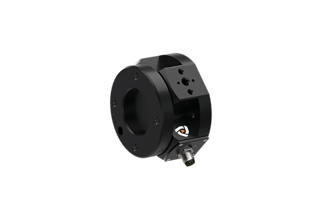

Mikado Find offers an easy-to-set-up complete package of camera and software for recognizing 3D objects.

Information about the Mikado Find software

Area illumination (400 x 300 mm) with infrared light (850 nm) for incident and transmitted light. Integrated controller for permanent and switching mode, control via digital I/Os. (Specification LG4030-KOL-IR850-V02)

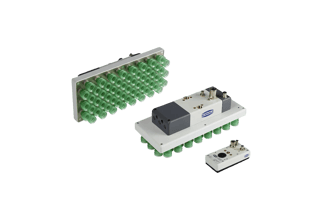

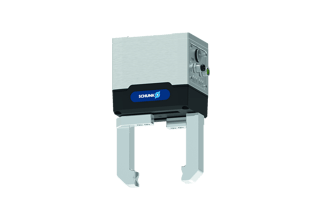

Electric 2-jaw parallel gripper (IO-LINK) from the GEP2000 series, small and compact, with variable adjustment of gripping force (4 levels) and jaw position. Only functional with HORST in conjunction with SCM module.

The adaptive shape gripper DHEF grips parts of different shapes and sizes safely and gently and enables fast installation and commissioning with HORST.

Ready-to-connect interface cable (incl. installation guide and sample program) for communication between HORST and injection molding machines via the Euromap 67 standard.

Further Information on the Euromap67 Standard

.webp?width=410&height=220&name=Trayhalterung%20eben%20(2).webp)

.webp?width=410&height=220&name=Trayhalterung%20schr%C3%A4g%20(2).webp)

The nanoSCAN3 PRO IO is a safety scanner for the HORST600 robot. It features a 3.0 m protection field range and supports safe speed reduction, making it ideal for use with the HORST600 on a mobile robot base.

Put together the automated solution for your application area yourself with just a few clicks and transparently determine your investment.

Robert Meißner / Senior Expert Manufacturing Technologies, Research & Development at fischer group

Frank Reinauer / Senior Director Division Implants at Karl Leibinger Medizintechnik GmbH & Co. KG

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

Lorenz Geyer / Managing Director Eugen Geyer GmbH

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

Thomas Sehling / Operational Excellence Manager at WEBER-HYDRAULIK GmbH

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

Beat Glauser / CTO MBV AG

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

Siegmar von Detten / Computer science teacher at Zeppelin Gewerbeschule Konstanz

Daniel Weerts / Research assistant, Institute for Technology and Education (ITB), Bremen

Andreas Beck / Design technician for test equipment and fixture construction at the Villingen-Schwenningen plant

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de