Industrial robots in the metal industry

Automation with HORST:

Faster, more precise and more cost-effective production

Challenges for the metal industry: Robots as the solution?

The metal industry faces many challenges: Too few skilled workers, enormously high costs for personnel. If you don't increase efficiency and optimize quality and expenditure, you will quickly be out of the market. Added to this are increasingly complex processes and hardly any scope for rejects. Automation as a solution? Still too risky for many in the metal industry. But it is possible. If innovative automation solutions are used to avoid errors in operation or safety concerns in human-robot collaboration.

Future-proof with industrial robot HORST

Our advanced robotic solutions enable precise welding, machining and handling processes that reduce errors and increase product quality. Due to simple integration and intuitive control, we speed up your production cycles. Our solutions are flexible and reliable, relieve your skilled workers and increase the efficiency of your production. Rely on HORST to stay competitive and secure the future of your production.

Automate with HORST:

Keeping the metal industry fit for the future

Speed

With our revolutionary automation modules for machine loading and welding, you will experience a breakthrough in throughput and throughput time in production!

Flexibility

Is your production facility looking for a powerful, versatile and high-reach robot? Our solutions adapt at lightning speed - no matter what you produce.

Cost efficiency

With digital robots, you reduce production costs because you have less waste and rework. Automation also reduces your material and personnel costs. We keep maintenance costs low.

Simple integration

Our automation solutions can be quickly and easily integrated into your existing systems without the need for PLC programming.

Welding, milling and more: Automated applications for the metal industry

Welding processes

Our automation solutions ensure precise weld seams and consistently high quality. You save time, produce in ghost shifts or even 24/7 and increase your throughput.

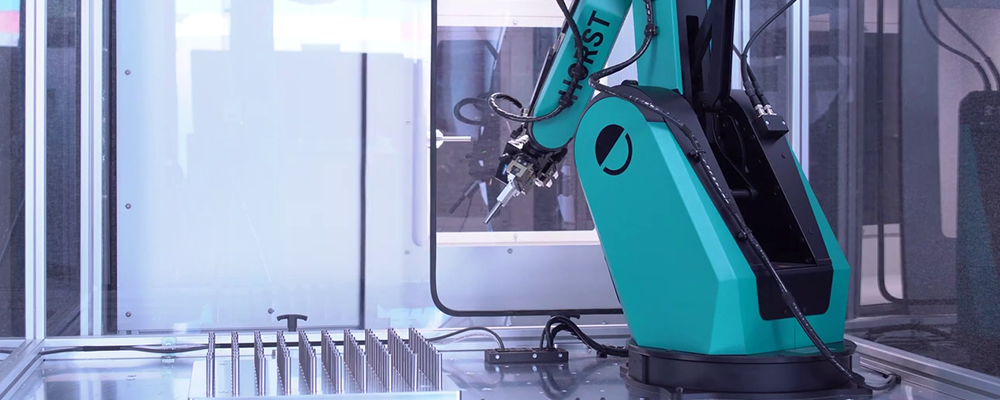

Material handling

Our automated systems make it easier for you to handle metal materials during all production steps. They take the strain off your employees, who can concentrate on the essentials.

Quality control

With our automation solutions for continuous monitoring of product quality, you can meet the highest demands. With industrial robots, you can reduce rejects and manual errors so that your products are of consistently high quality.

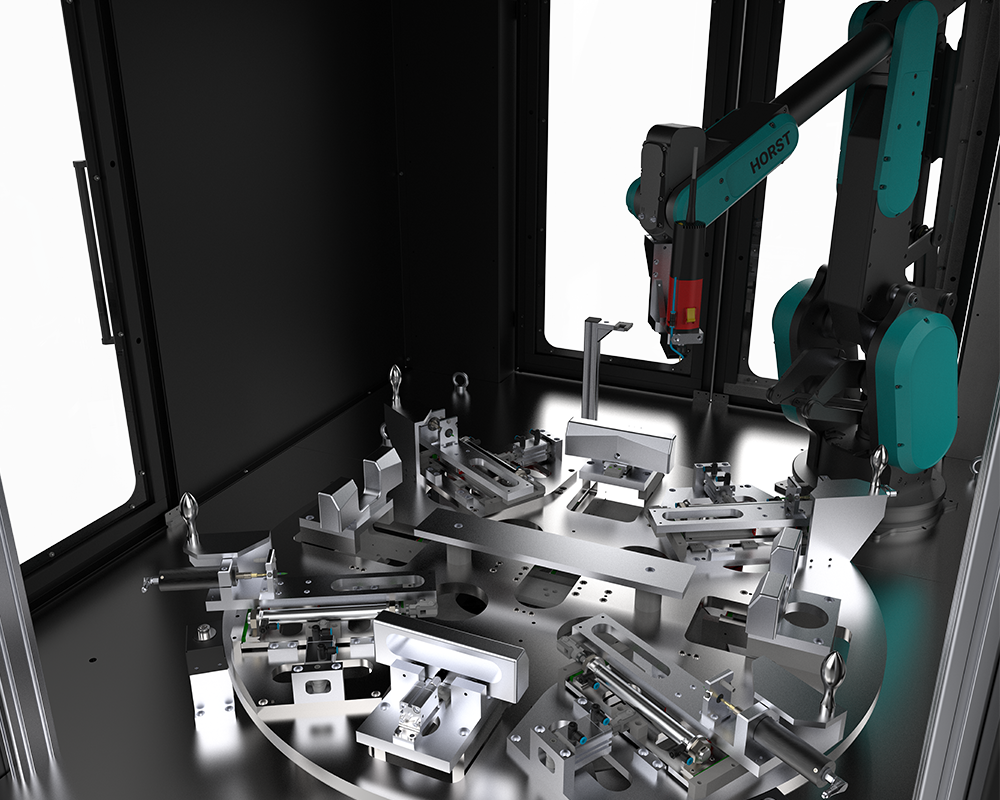

Machine loading

Automate the loading of CNC machines and other systems to make your manufacturing processes more efficient. Our solutions shorten throughput times and improve your productivity.

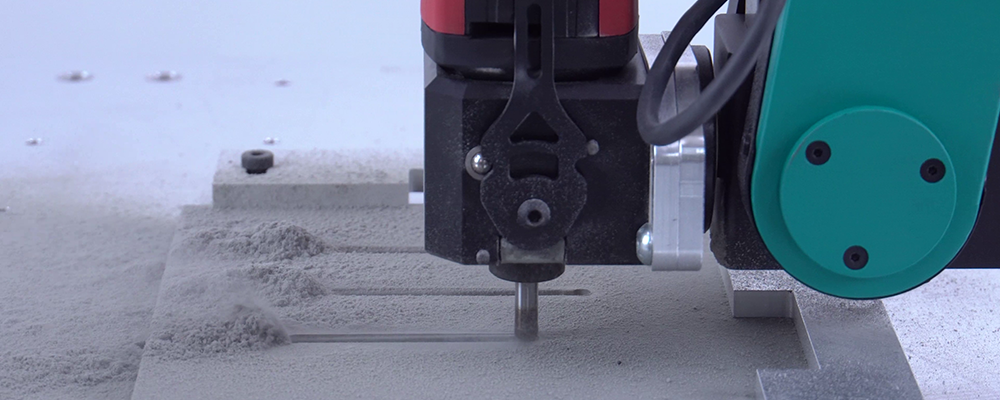

Machining processes

Switch to automated machining for milling, turning and drilling. This ensures maximum precision and therefore consistent quality throughout the entire process.

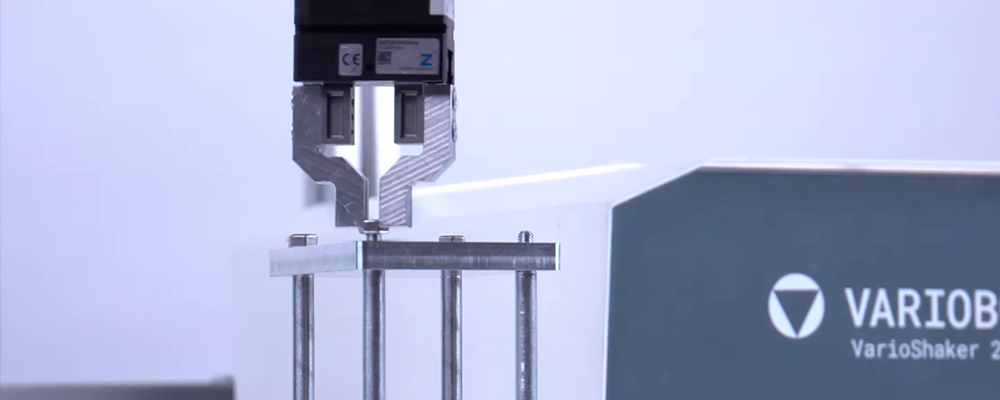

Assembly

With our precise automation solution for the assembly of metal components, you can produce faster and with fewer errors.

Talk to us:

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de