Maximum efficiency and precision in the plastics industry

Error-free processes, fast changeover, intuitive operation - with industrial robots

Mastering the challenges of plastics processing

High energy and raw material costs as well as enormous material consumption require constant process optimization in the plastics industry. An additional challenge: It is difficult to achieve consistent results in typical industry processes such as injection molding, extrusion or blow molding. You can counter this with automation and avoid long cycle times and low productivity. However, many people fear the complex and expensive integration of robots into their production system. The plastics industry in particular needs innovative automation technology that offers the necessary flexibility to produce efficiently.

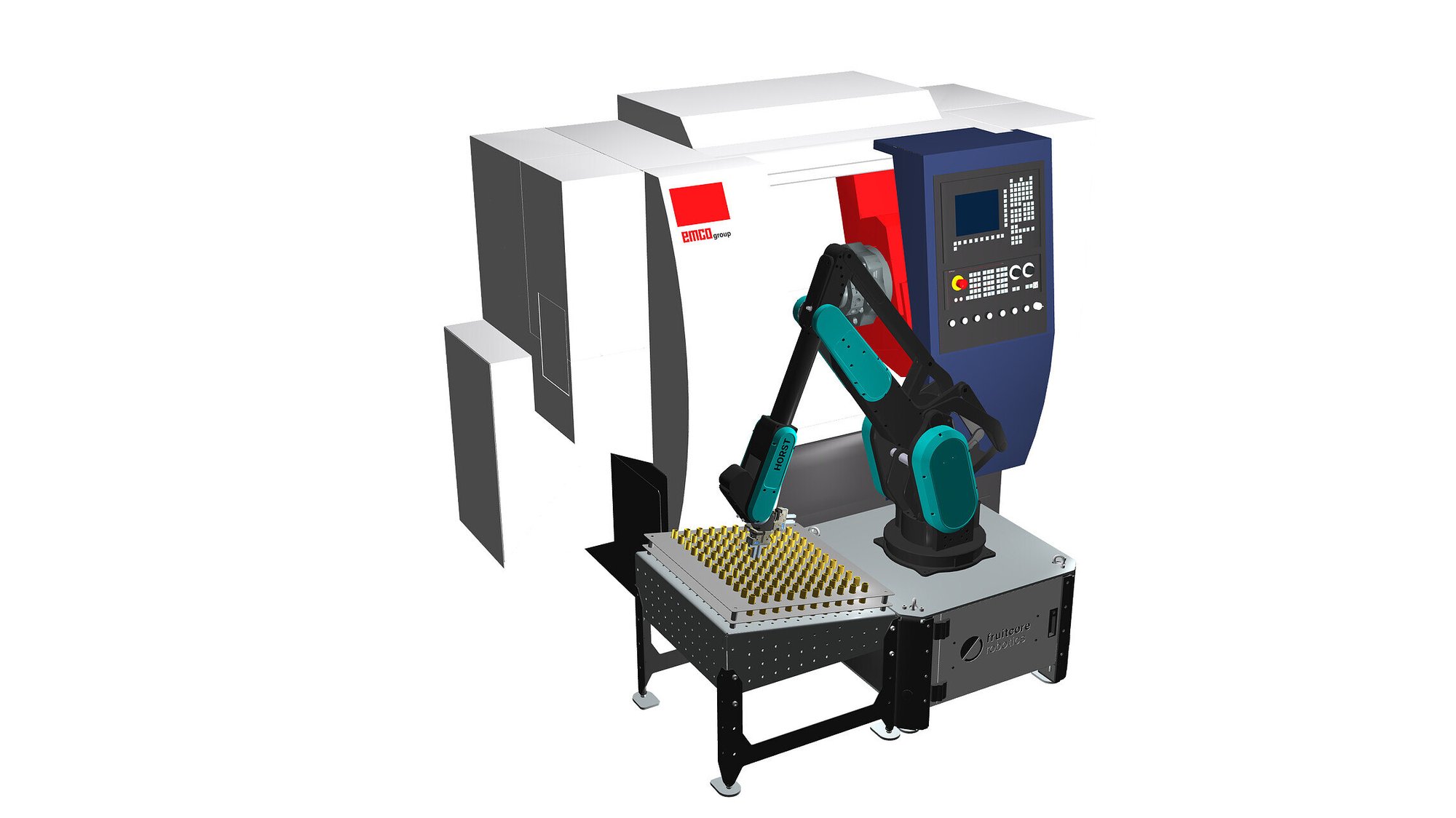

Into the future of plastics production with the HORST industrial robot

Precise injection molding and extrusion processes, combined with automated post-processing, increase product quality by avoiding errors and reducing waste. Product cycles are accelerated thanks to simple integration and intuitive control systems. Our flexible automation solutions offer high efficiency, even with the smallest batch sizes, and increase your productivity.

HORST - the versatile robotics solution for the plastics industry

Ensuring secure processes

Reduce errors in the handling of plastic parts with automated pick-and-place applications for consistently high quality.

Convert systems quickly

Our HORST robot and its components adapt flexibly to different production batches so that you can react quickly to new requirements.

Significantly relieve employees

Our solutions take over monotonous and potentially unhealthy tasks so that your employees can concentrate on value-adding activities.

Operating robots intuitively

Control your processes easily and efficiently with the Digital Robot Platform. With our integrated control software, your employees do not need any robot or programming experience.

Applications for the plastics industry: HORST can help you here

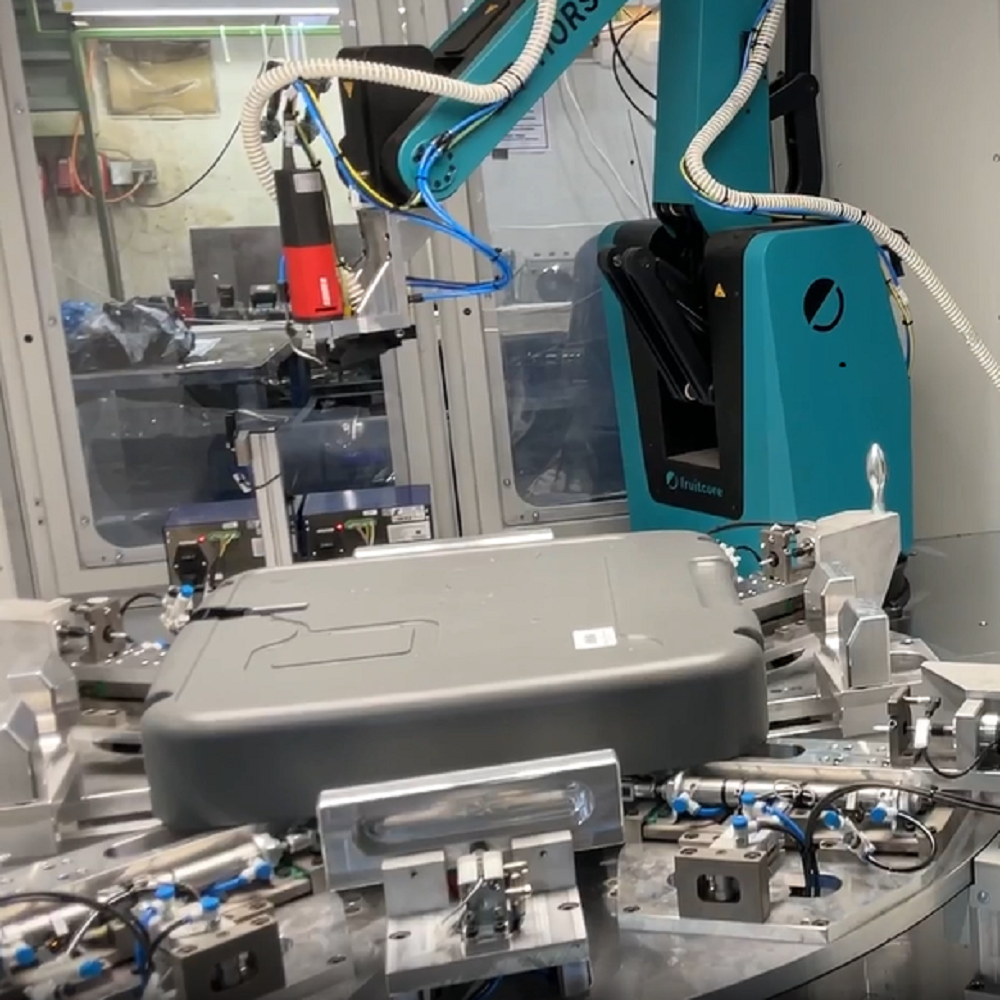

Injection molding

Automate the fast and reliable loading of your injection molding machines and the precise removal of parts. Automated quality controls significantly increase your production cycles.

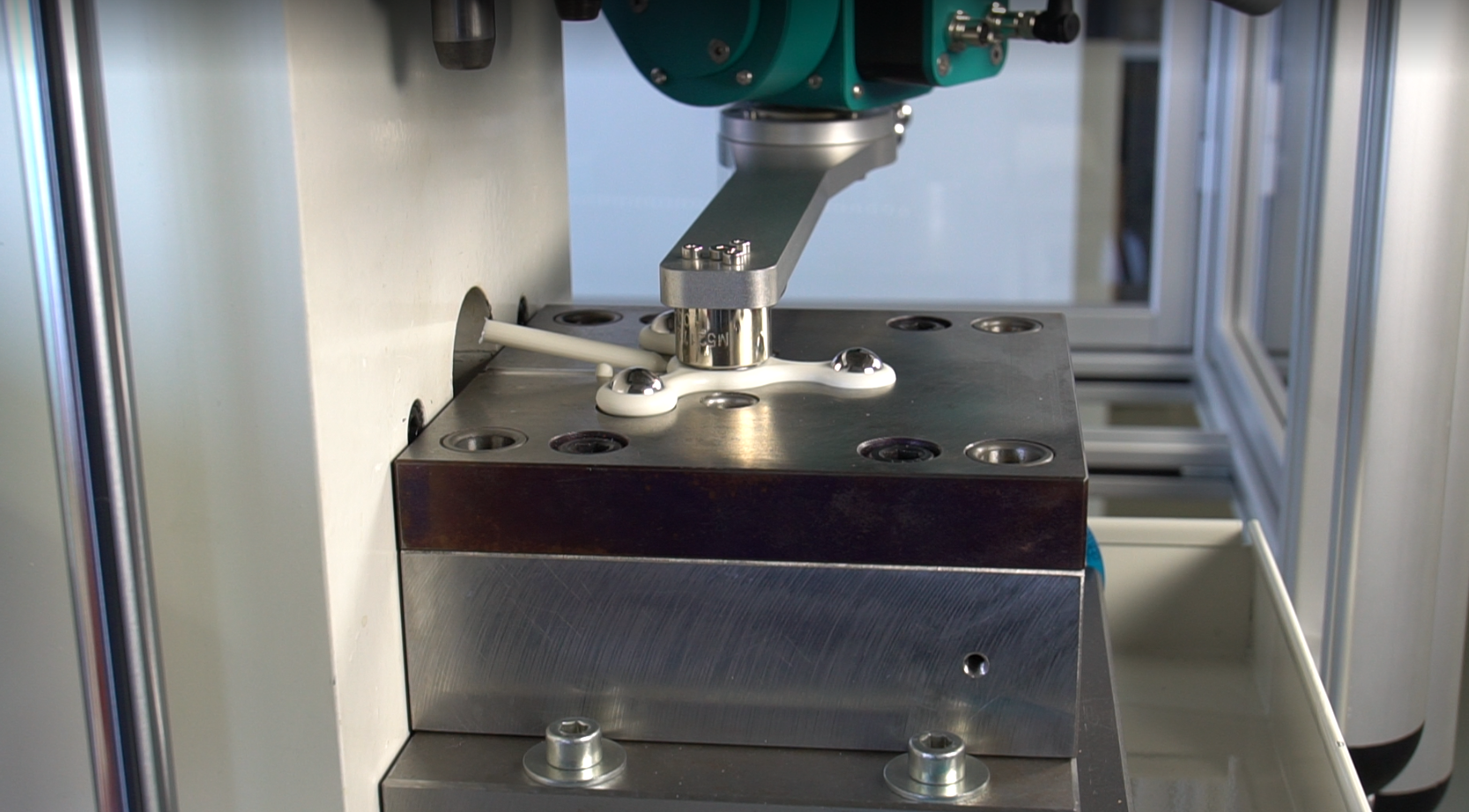

Assembly

Our automated systems shorten assembly times, reduce errors and cut waste when assembling your plastic components.

Testing

Automated quality controls ensure fast and reliable inspections. The integration of measurement technology optimizes data acquisition and analysis and increases your quality standards.

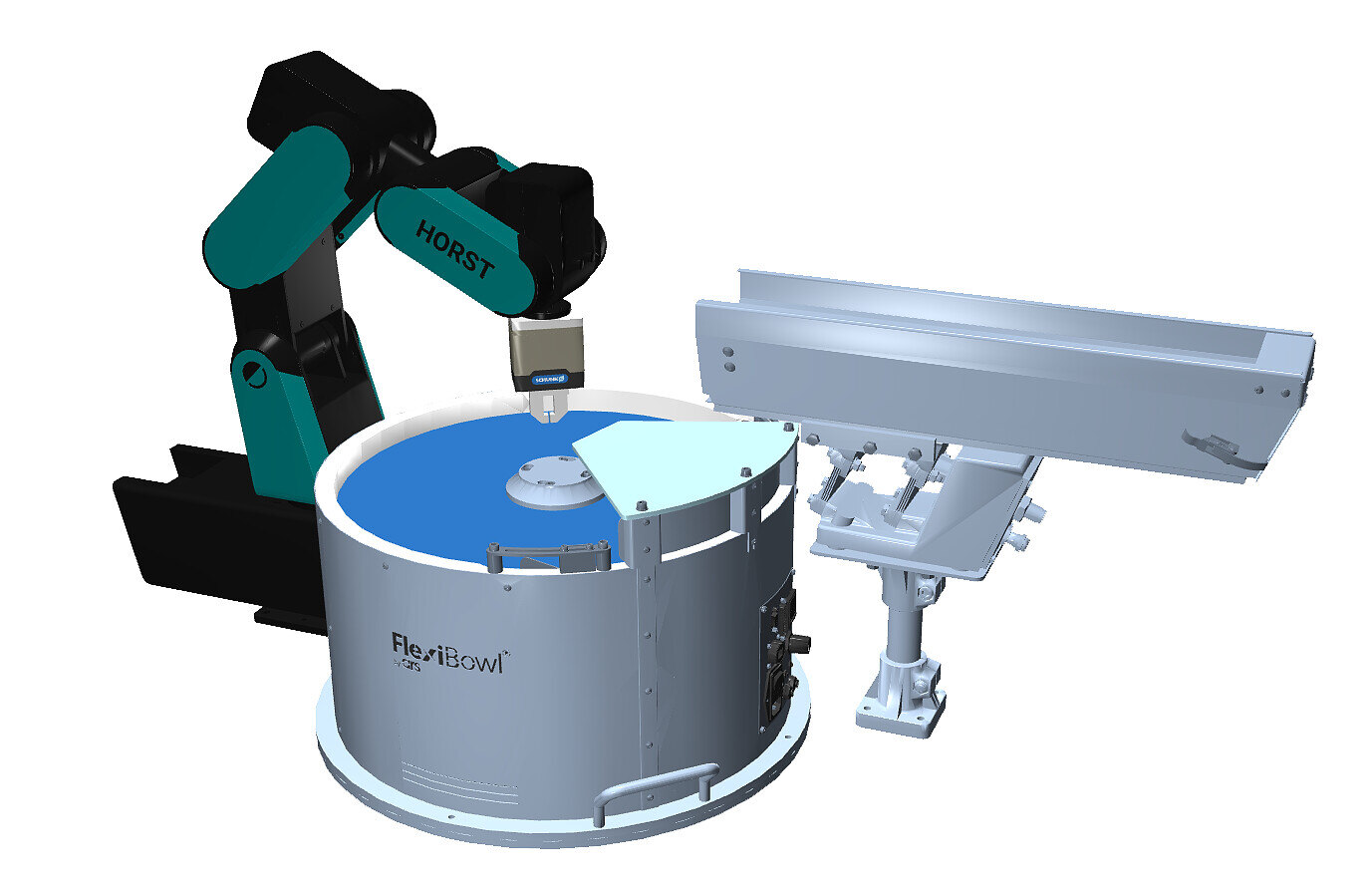

Sorting and separating

Increase the efficiency of your systems with fast and precise sorting and separating systems that can be flexibly integrated and adapted.

Talk to us about your specific requirements

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de