Customized automation for every requirement

Find the perfect solution for all applications

Discover the world of intelligent automation with our innovative industrial robots and versatile modular system. Increase your efficiency in almost any industrial application and reduce the burden of tedious tasks on your employees.

More efficiency, quality and productivity: Do these challenges sound familiar to you?

Which processes in your company could be more efficient, of higher quality and more productive? Find out more about frequently overlooked risks and problems in industrial production - from a lack of precision in pick and place to inefficient separations and inaccurate quality controls to specific processes such as gluing & dispensing.

Master the challenges of the industry with HORST

Quickly and efficiently find a user-friendly solution with our holistic approach to automation. The HORST robot and our patented modular automation system are designed to optimize key areas of production: from flexible machine tending, efficient part separation and precise quality control to complex applications such as gluing and dispensing.

HORST is just the beginning

Fast project planning with our patented modular system saves you considerable time and effort compared to conventional automation projects. Avoid additional costs thanks to preconfigured solutions from a single source.

Our Solution Kits - preconfigured and ready to use

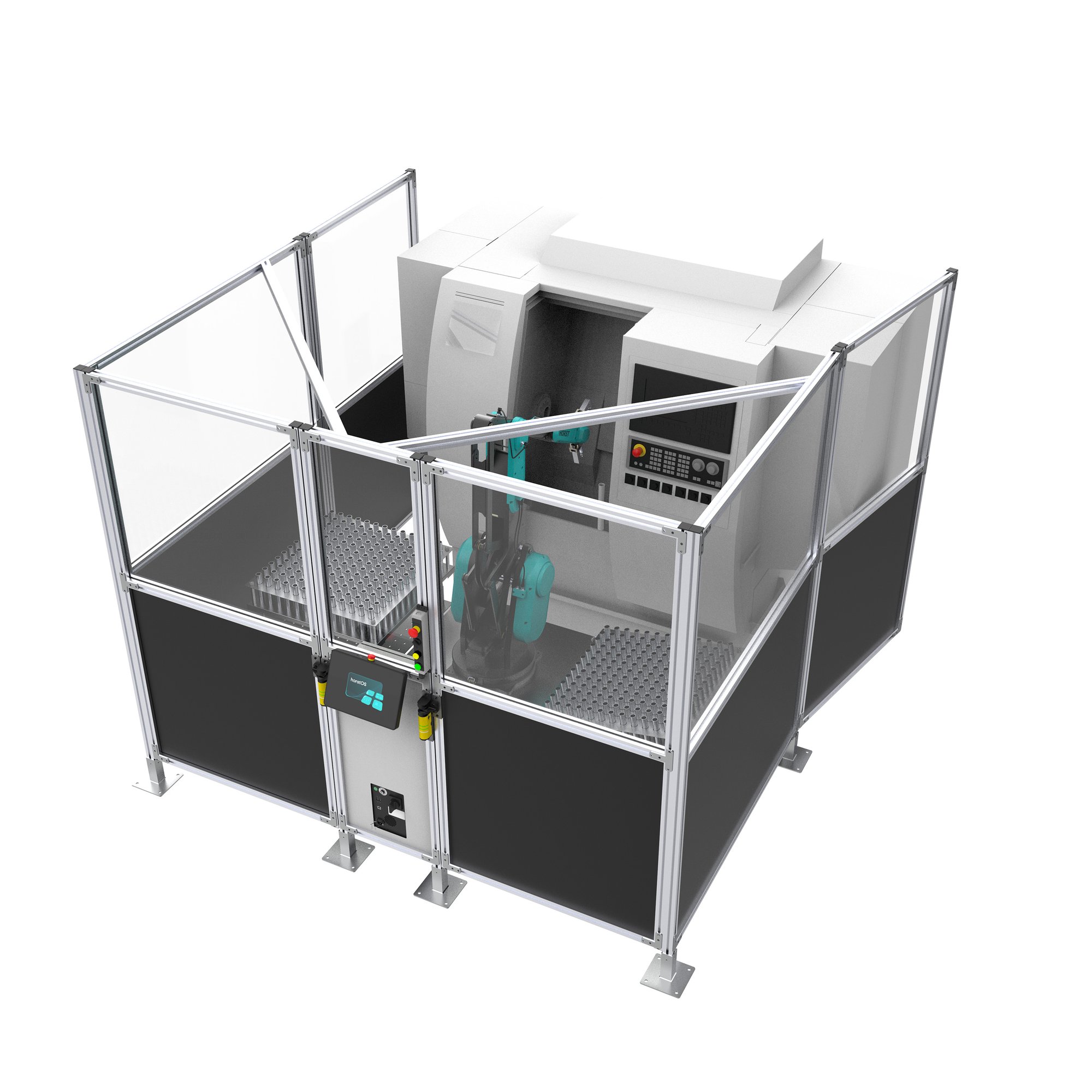

Solution Kit machine tending

With HORST, you can revolutionize the loading and unloading of your machines. Our ready-to-use, CE-certified automation modules excel with the fastest installation and changeover. Program the work with multiple grippers as easy as never before with our ready-to-use graphical programs. You can connect additional machines to the system cost-effectively without an additional PLC.

Maximum flexibility in parts separation

Our automation module enables flexible separation of a wide variety of parts, which you can expand to suit subsequent processes. You can set up new parts within minutes thanks to preconfigured software. This allows you to react immediately to changing requirements. You can seamlessly integrate automation with the Digital Robot HORST into your existing systems.

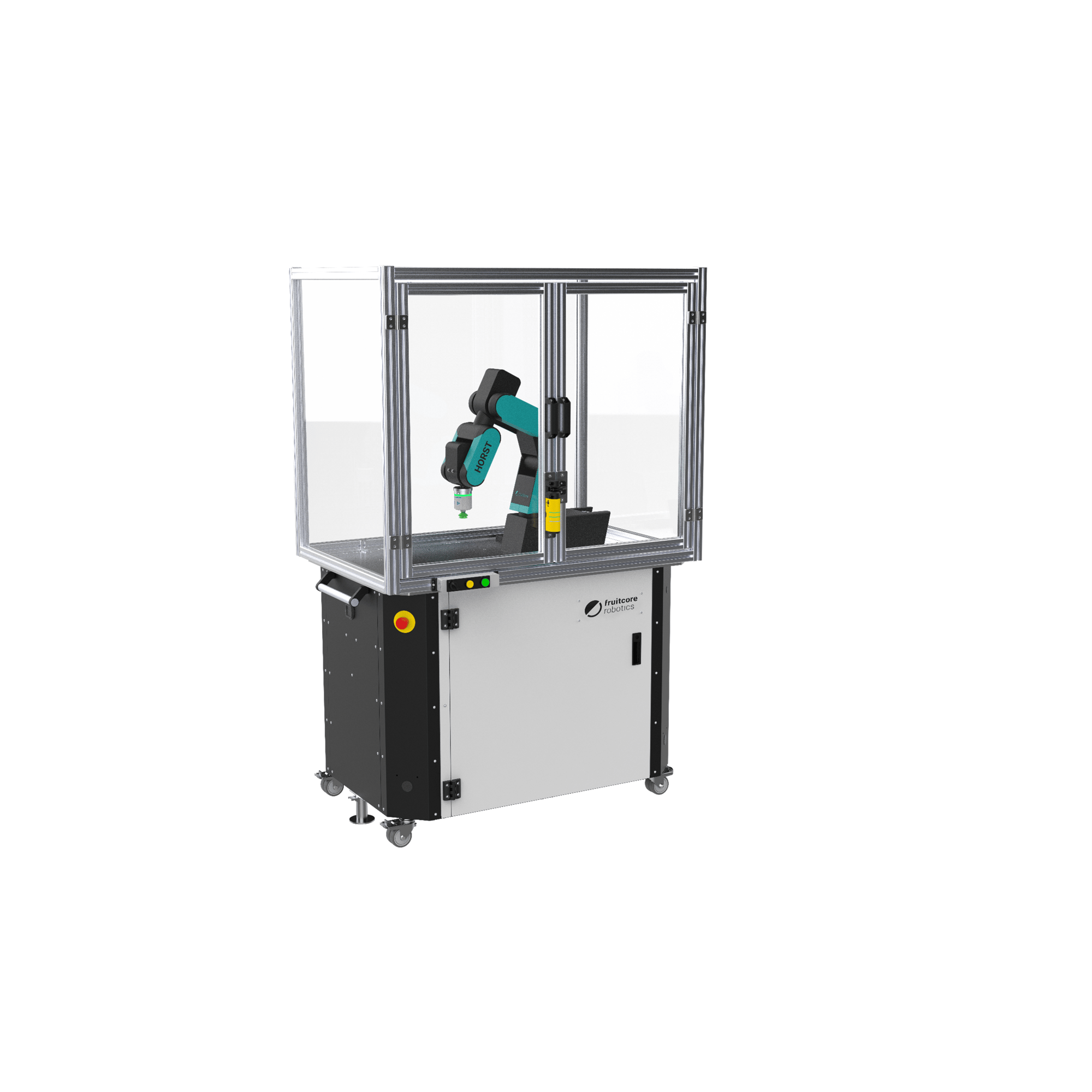

The easy way to automation with the Pick & Place Solution Kit

Do you want to automate your production processes as smoothly and efficiently as possible? Our Pick and Place Solution Kit has been developed to do just that! With intuitive operation and user-friendly software, this complete solution is ready for you to use straight away.

Solution Kit Education -Getting in shape for modern work

There is no way of avoiding the use of automation and robots in industry. With the Digital Robot HORST and the appropriate learning platform, you can give students a significant knowledge lead in no time at all!

Create your individual offer

Configure your automation solution with just a few clicks and find out transparently the price for your project!

- Choose the right HORST including software for your application.

- Extend your advantage in the market with additional software options.

- For the best results, choose one of our affordable all-inclusive packages.

Are you curious? We would be happy to advise you!

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de