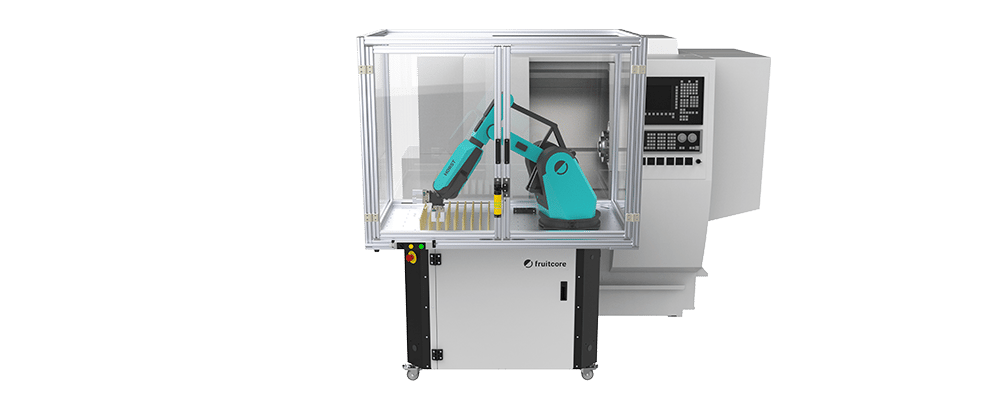

Solution Kit Machine Tending I

The mobile automation module for machine loading

%20Kopie.webp)

Load and unload machines efficiently

With our preconfigured Machine Tending I solution kit, you can achieve the shortest installation and changeover times as well as maximum adaptability for your application.

The best cost efficiency and flexibility for loading your machines: This solution for automated loading and unloading of all common machine tools makes this the norm for you. The solution kit can be flexibly positioned on machine tools using a locking device.

Components of the Solution Kit Machine Tending I

- Mobile Robot Base L (MRB)

with protective fence and safety interlock - Digital Robot HORST1000

- Control system “Control”

- Control unit “Panel”

- Double gripper

with blow-off unit - Operating console

Specifcations,Product Details of our automation solution for machine placement

| Detail | Specification |

|---|---|

Dimensions |

1532 x 1101 x 2054 mm |

Total weight |

approx. 312 kg |

Maximum part weight |

3 kg (recommended 1.75 kg) |

reach in machine |

up to 700 mm |

Loading time |

approx. 12 seconds (incl. removal, blowing off and insertion) |

Recommended tray size |

500 x 500 x 300 mm (square), 600 x 400 x 300 mm (rectangular) |

Autonomy time |

approx. 60 minutes with 100 parts, 12 seconds loading time and 20 seconds machine processing time |

Suitable machines |

Emco, Hurco, Haas, Trumpf, Foba and many more |

All from one single source: Your advantages with this Solution Kit

Only 15% of the usual project effort

Keep the lead time and costs for starting your automation project to an absolute minimum. Thanks to predefined programs and prepared interfaces for all common machine tools via Harting connectors. You also benefit from the low energy consumption of the overall solution.

Full flexibility, simple job changeover

This solution kit uses our tried-and-tested mobile robot platform with repeatable fasteners and a base plate with a 100x100mm grid of M8 threaded holes. This allows you to easily switch between different applications.

Simple and centralized operation

The Solution Kit is programmed and controlled centrally via the horstOS control software. You do not need an external control system (PLC).

Short machine idle times for higher outout

Save costs and increase the efficiency of your production. With this automation module, you can achieve optimal utilization of your machines. The machine idle time between the end of machining and the start of the next machining operation is only about 12 seconds, including blowing off the finished part and the collet.

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Beat Glauser / CTO MBV AG

HORST is inexpensive to purchase, requires little space, can be used flexibly and is easy to handle thanks to intuitive operation with the horstFX robot software.

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Above all, the flexible applicability of HORST convinced us. In addition, the price-performance ratio fits and we simply have a team at our disposal that flexibly implements the individual task with us.

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

The great advantage of HORST and the control system is that it can be used completely flexibly in an SME. I don't need highly trained technical personnel who are specialized in the application with or programming of robots, but can also train the normal machine operator on HORST.

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

Download detailed information on the Machine Tending solution kit

Please contact us for specific requests and questions

Our Solution Kits offer flexible customization options, including the use of individual components and the integration of additional process steps. Feel free to contact us for individual offers and discover the optimal solution for your requirements.

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de