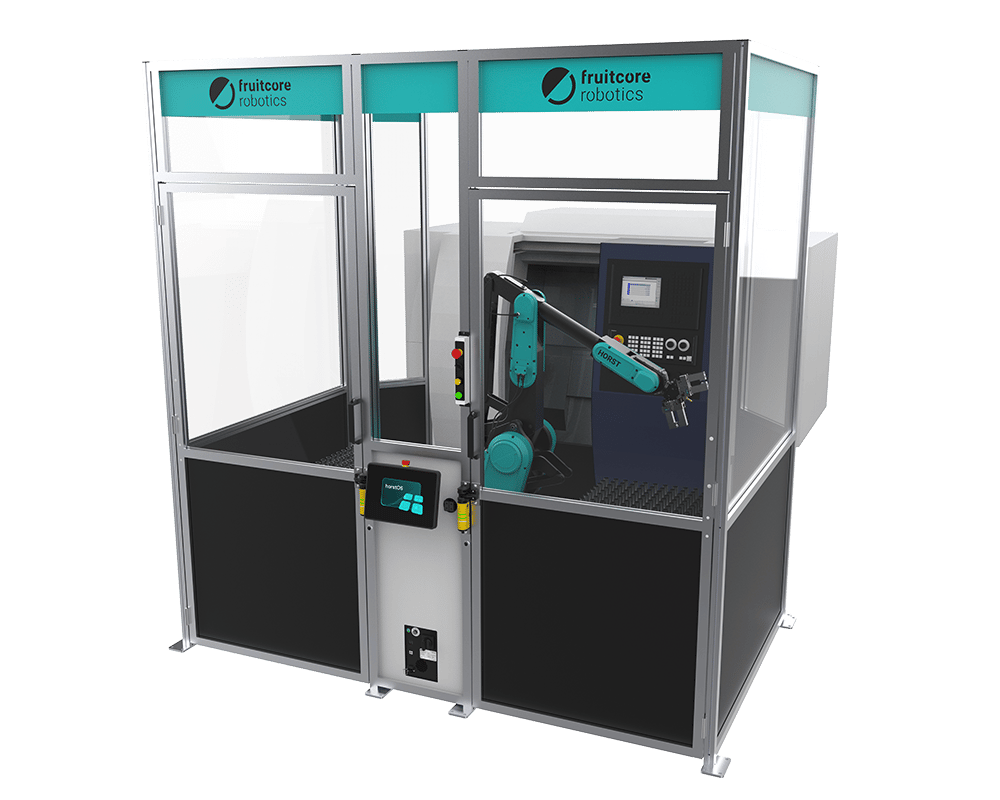

Solution Kit Machine Tending II

Modular concept for efficient machine loading and unloading

Contact us now

.webp)

The efficient way to load and unload machines:

The modular Solution Kit can be configured as required and enables maximum autonomy times thanks to flexible parts provision. Short machine intervention times can be achieved thanks to the double gripper.

The modular Solution Kit Machine Tending allows you to automate the loading and unloading of machine tools with minimal effort and maximum efficiency. The Solution Kit consists of several standardized Component Kits that can be individually assembled for your specific application. This provides the highest level of flexibility in project planning at the lowest cost.

Components of the Solution Kit Machine Tending II

- Robot Base with 2 tray holders incl. feet

- Digital Robot HORST1500 G2

- Control system "Control"

- Operating panel "Panel"

- Double gripper with blow-off unit

- Operating console

- Modular robot fence with 2 doors incl. safety lock

Specifications,Productdetails of our automation solution for machine loading

| Data | Specifications |

|---|---|

Tradable part weight |

max. 4.5 kg with double gripper |

Range in machine |

Up to 1100 mm depending on screw-on position |

Assembly time |

approx. 12 sec with removal, blowing off and insertion |

Recommended tray size |

Standard size of the tray holder 672 x 672 mm |

Autonomy time |

Individually definable via the selection of parts provision via 1 to 3 tray holders or via directly dockable pallets |

Compatible machines |

Emco, Hurco, Haas, Trumpf, Foba and many more (also special machines) |

Available component kits |

Robot base, tray holder, feet, positioning unit, SCHUNK double gripper with blow-off unit, robot fence (base element, door element with safety lock, long/short element) & machine interface |

Modularity |

The available component kits can be individually combined for your application. We will be happy to advise you on this and provide you with a customized offer |

Your advantages at a glance

Only 15 % of the usual project costs

The compatibility of all Component Kits is always ensured. Thanks to the plug-and-play interface with the machine, you are ready to go with the Solution Kit immediately - much faster than with a special solution

High autonomy

Design parts provisioning according to your individual requirements and maximize the autonomy time of your machine loading. This allows you to achieve maximum output.

Simple and centralized operation

The Solution Kit is programmed and controlled centrally via the horstOS control software. You do not need an external controller (PLC).

Maximum efficiency

The short loading time, including blowing off the finished part and the chuck, ensures minimal machine downtime, maximizing output

Exclusive special deal: Solution Kit Machine Tending 2 with HORST1400

Now with 20% discount

HORST1400: Take advantage of its reach and power

The advantages of this intelligent digital robot lie in its high load capacity, which you can make optimal use of thanks to our innovative, self-developed robot gearbox. Its long reach also allows you to load more distant machines with precision.

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Beat Glauser / CTO MBV AG

HORST is inexpensive to purchase, requires little space, can be used flexibly and is easy to handle thanks to intuitive operation with the horstFX robot software.

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Above all, the flexible applicability of HORST convinced us. In addition, the price-performance ratio fits and we simply have a team at our disposal that flexibly implements the individual task with us.

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

The great advantage of HORST and the control system is that it can be used completely flexibly in an SME. I don't need highly trained technical personnel who are specialized in the application with or programming of robots, but can also train the normal machine operator on HORST.

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

Download detailed information on the Machine Tending solution kit

For specific requests, please contact us

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de