Case Studies and references with HORST: Success stories of our customers

Discover how companies can increase the productivity and availability of their use cases thanks to intelligent Digital Robots. Find out how your employees can be relieved of monotonous and repetitive tasks.

Case Studies

You can learn about the advantages of using intelligent industrial robots in many applications, such as parts handling or pick-and-place use, by reading the success stories of our customers.

Referenz Videos

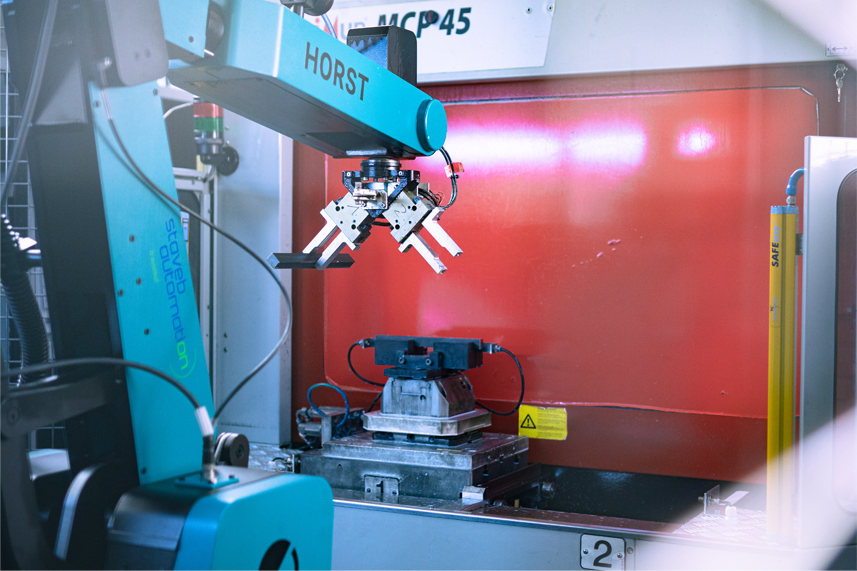

Using the Digital Robot HORST forming gripper for small parts

Digital Robot HORST inspects surfaces with Surface Inspection Tool from 8tree

HORST600 lab

Digital Robot HORST as a quick-start bundle for immediate automation

Solution Kit Part Separation as complete solution for automation

Digital Robot HORST for workpiece handling Loading of laser cutters

Digital Robot HORST for automated palletizing

Digital Robot HORST1000

Digital robot HORST with pick and place tasks at Photon

IIoT-Plattform horstCOSMOS

Robot Software horstFX: Release 2023.04

Robot Software horstFX: The most important Feature Releases

Digital Robot HORST on tour at Automatica 2023

Quality Inspection with INSPEKTO S70-system and HORST600

Digital Robot HORST loads hydraulic press at Roth & Effinger GmbH

Digital Robot HORST loading and unloading a laser system at MBV AG

Digital robot HORST uses striking plates at Gerdes GmbH

Automated palletizing of circular knives at Doppkon GmbH & Co. KG

What our customers say:

We use the test cell for technological feasibility analyses and innovations in product development and are thrilled. The Solution Kit can be put into operation, programmed and operated quickly and easily without any special prior knowledge.

Robert Meißner / Senior Expert Manufacturing Technologies, Research & Development at fischer group

With HORST, we are very well positioned in our test lab. The compact footprint is very convenient and the usability of the robot is a great advantage, especially for the complex test setups.

Frank Reinauer / Senior Director Division Implants at Karl Leibinger Medizintechnik GmbH & Co. KG

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

Marius Effinger / Project Coordinator at ROTH&EFFINGER GmbH

The high quality demands placed on our products require first-class quality assurance. By using the HORST industrial robot, we have not only created the best testing conditions, but also significantly increased product quality. The robot has relieved our employees of monotonous tasks as well as led to an increase in productivity and a high level of satisfaction among our customers.

Lorenz Geyer / Managing Director Eugen Geyer GmbH

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

Fabian Pfister / Co-Founder and Managing Director at CyFa-Tech.ch Manufacturing Solutions GmbH

HORST takes over typical pick & place tasks for us during a hydraulic test and enables a fully automated testing process. As a result, we achieve a significantly higher output and increase our productivity. We were also convinced by the easy operation of the industrial robot, the good price and the comprehensive support from fruitcore.

Thomas Sehling / Operational Excellence Manager at WEBER-HYDRAULIK GmbH

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

Stefan Schirling / Junior Owner at Schirling Frästechnik GmbH

HORST is inexpensive to purchase, requires little space, can be used flexibly and is easy to handle thanks to intuitive operation with the horstFX robot software.

Matthias Schneider / Plant Manager at Koepfer Zahnrad- und Getriebetechnik GmbH

Above all, the flexible applicability of HORST convinced us. In addition, the price-performance ratio fits and we simply have a team at our disposal that flexibly implements the individual task with us.

Dominik Pfeiffer / General Manager at add'n solutions GmbH & Co. KG

The great advantage of HORST and the control system is that it can be used completely flexibly in an SME. I don't need highly trained technical personnel who are specialized in the application with or programming of robots, but can also train the normal machine operator on HORST.

Peter Imm / Owner and General Manager at imm Cleaning Solutions GmbH

We were able to initialize HORST within a very short time and thus get started directly with program applications. The operating panel is very pleasant to use.

Siegmar von Detten / Computer science teacher at Zeppelin Gewerbeschule Konstanz

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Beat Glauser / CTO MBV AG

Your contact to fruitcore robotics

Do you have further questions about our unique automation solutions or already have a specific application in mind that you would like to automate and optimize with us? Do not hesitate to contact us. We look forward to discussing your individual needs and developing innovative solutions for your company together.

fruitcore robotics GmbH

Macairestraße 3

78467 Konstanz

+49 (0) 7531 976 240

info@fruitcore.de