2 min read

Automation with industrial robots: As easy as riding a bike

Markus Mayr

:

Aug 1, 2022 2:33:00 PM

Markus Mayr

:

Aug 1, 2022 2:33:00 PM

Small and medium-sized enterprises (SMEs) are more challenged than ever in terms of competitiveness and skilled labor shortage. For the first quarter of 2022, the Institute for Employment Research reported almost 1.75 million open positions - a record. This affects almost all industries. Automated solutions are becoming particularly intriguing for many SMEs.

With a new generation of robots, automation is becoming increasingly accessible for medium-sized businesses. Can SMEs overcome one of the biggest hurdles - complex programming - that has previously hindered their entry into robotics with this new generation of robots? The answer is yes.

Thanks to innovative software, getting started is a breeze

You're probably familiar with the huge, complex-to-operate industrial robots found, for example, in the halls of car manufacturers. Now, they're being complemented by a new generation of robots: the era of Digital Robots has arrived. They're simpler, digitally connected, and significantly more cost-effective than their massive counterparts. Their advantage: they can be used for a wide range of applications without prior knowledge or extensive robotics training. Automation with robots becomes as easy as riding a bike with them. This means even SMEs without extensive automation experience can position themselves for the future.

Digital Robots: The software is as intuitive as a smartphone

So if you've been concerned about the complex programming when working with robots in the past, those concerns are unfounded today. Providers of Digital Robots have made it their mission to make entering the world of robotics as easy and intuitive as possible. Do you use a smartphone? Then you're also capable of operating a robot in an industrial setting.

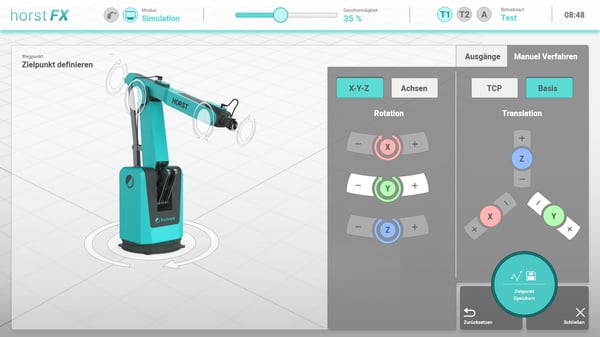

For a large portion of applications, you don't need specialized and extensively trained experts. Digital Robots can be set up and operated using graphical interfaces without the need for programming knowledge. The intuitive software replicates the entire application through a digital twin. This not only speeds up the setup and operation of the physical robot but also connects all the components integrated into the robot system. This is a significant advantage for entering the field of robotics.

Why simpler operation does not mean fewer possibilities

The simplification of robot control software does not mean that you will be left alone. Many robot providers offer their customers deeper insights into the world of Digital Robots, for example through webinars or video tutorials. Perhaps you have already seen one on YouTube.

Videos, tutorials, and webinars allow users to delve deeper into the subject and empower themselves through the DIY process. The responsible professionals can take steps from simple usage to more complex cases on their own and later, if necessary, also venture into textual programming.

No matter how long the journey is...

...at the beginning, there's the challenging first step - or in the case of riding a bike, those first meters without training wheels. But it's precisely these initial pedal strokes that are worth it: After that, it gets easier! Thanks to the intuitive software, engaging with robotics has never been easier. In the fiercely competitive market, it's crucial for small and medium-sized enterprises to get in early, because the effort required is low! An easy-to-use Digital Robot can be the decisive step towards competitiveness and away from the skilled labor shortage.

Want to learn more about Industrial robots, Digital Robots and how easy they are top setup? Click here