Article

Article

HORST1000 G2: der stärkste Industrieroboter seiner Klasse

Nach dem erfolgreichen Markteintritt von HORST1500, dem ersten Industrieroboter der neuen...

At Motek 2024, fruitcore robotics will be presenting innovative, AI-supported automation solutions for machine loading and parts separation. In Hall 7, Stand 7204, visitors will experience the latest generation of industrial robots, customized solution kits and the intelligent horstOS control software in action. The simple setup and operation of the systems using horstOS and the integrated AI Copilot can be tested on site.

Geposted von:

Sylvie Rest

At Motek 2024, fruitcore robotics will be presenting innovative, AI-supported automation solutions for machine loading and parts separation. In Hall 7, Stand 7204, visitors will experience the latest generation of industrial robots, customized solution kits and the intelligent horstOS control software in action. The simple setup and operation of the systems using horstOS and the integrated AI Copilot can be tested on site.

In times of global competition, increasing cost pressure and a shortage of skilled workers, the automation solutions from fruitcore robotics offer a decisive advantage: they optimize production processes quickly and efficiently with minimal project effort. The solution kits are tailored to different production scenarios and integrate seamlessly into existing processes, enabling companies to achieve significant time and cost savings.

At Motek 2024, fruitcore robotics will be presenting the Part Separation Solution Kit and the latest modular Machine Tending II Solution Kit. The latter consists of standardized component kits and can be individually configured for specific applications. This enables fast and flexible adaptation to both production requirements and various machines such as CNC machines, presses, laser and injection molding systems. With flexibly configurable parts provision and the use of a double gripper, the Machine Tending II solution kit offers maximum autonomy times and short machine intervention times.

HORST1500 will be presented at the trade fair as a central component of the Machine Tending II solution kit. This industrial robot of the latest generation, developed for machine tending and palletizing processes, impresses with its fast cycle time. With a reach of 1485 millimetres and a payload of up to 15 kilograms, it is extremely versatile. Its compact design and maneuverability enable maximum flexibility in confined spaces, while its ability to position itself close to machines allows it to reach deep into the work area.

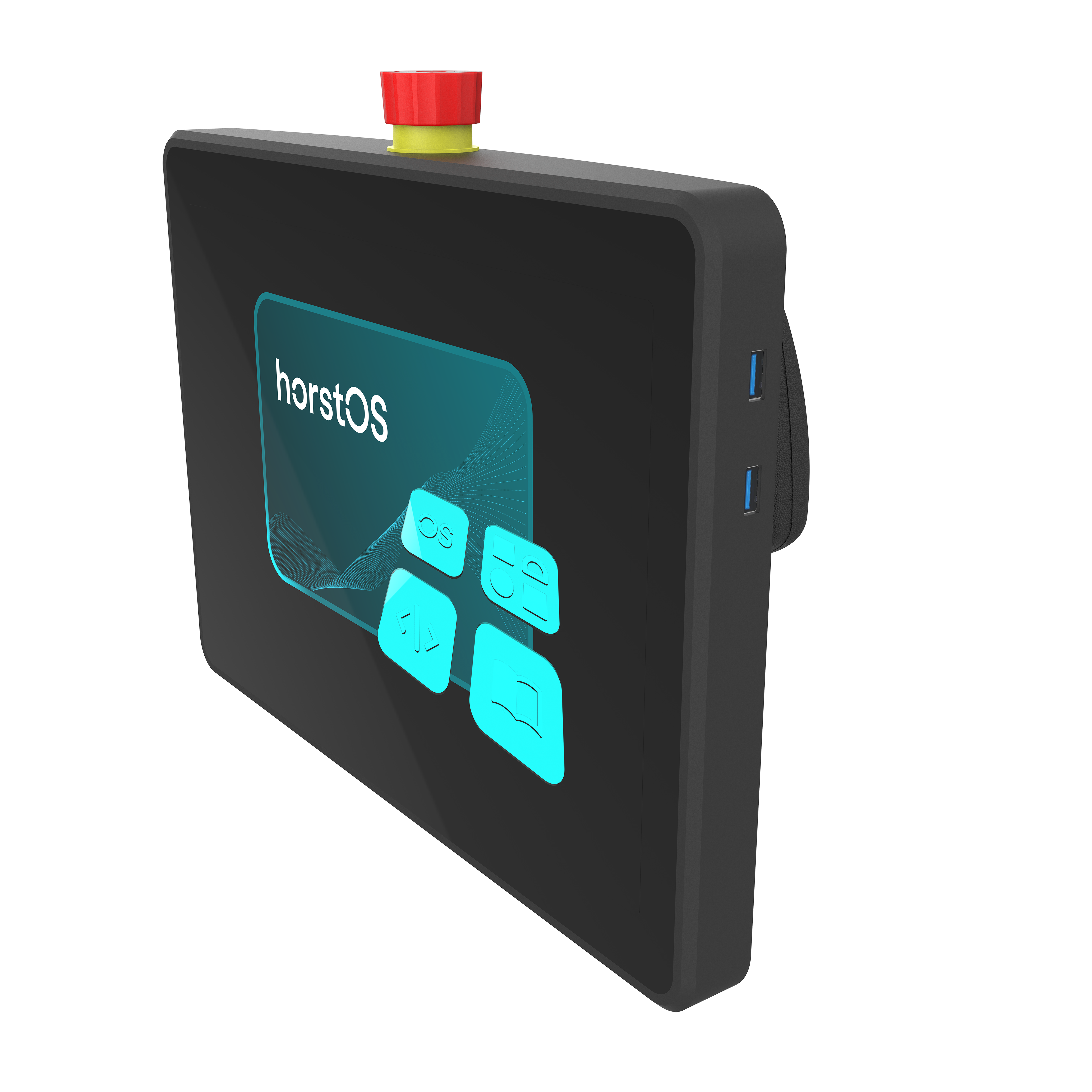

horstOS is the central control software for automation with HORST. It provides efficient support for setting up, programming and controlling processes and makes it easy to implement complete applications thanks to 3D visualizations and predefined programs. The integrated AI Copilot helps in natural language and makes the implementation of automation projects even faster and more efficient.

fruitcore robotics will be offering a comprehensive insight into the latest developments and technologies of its Digital Robot Platform at Motek 2024, complemented by exciting live demonstrations and practical applications. One particular highlight will remain a secret until the trade fair and will be unveiled there exclusively.

We will be happy to provide you with high-resolution images. Please contact us at presse@fruitcore.de

Article

Article

Nach dem erfolgreichen Markteintritt von HORST1500, dem ersten Industrieroboter der neuen...

Sylvie Rest

October 8, 2024

Article

Article

Auf der Motek 2024 präsentiert fruitcore robotics innovative, KI-gestützte...

Sylvie Rest

September 3, 2024

Article

Article

fruitcore robotics bringt ein neues Bedienpanel für seine Industrieroboter auf den Markt. Das neue...

Sylvie Rest

July 2, 2024