3 min read

Robot-assisted automation: solutions for automotive suppliers

Benjamin Brumm

:

Jan 8, 2025 9:25:56 AM

Benjamin Brumm

:

Jan 8, 2025 9:25:56 AM

The German automotive industry is undergoing profound change - and with it its suppliers, which are characterized by medium-sized companies. Thousands of companies produce and process metal components such as battery parts, electronic modules and mechanical parts for the automotive sector. The transition from combustion engines to electromobility, economic uncertainties and increasing competitive pressure require innovative solutions in order to remain competitive.

Robot-assisted automation offers promising approaches here.

Challenges in metal processing for the automotive industry

- Structural change due to electromobility: The switch to electric drives is changing the demand for specific components. Traditional components are needed less, while new components, especially for batteries and electronic systems, are gaining in importance. Companies must adapt their production processes accordingly.

- Economic uncertainties: Recessions, fluctuating markets and unpredictable relationships with key export countries such as China or the USA are also leading to a decline in orders for suppliers and increasing pressure on margins. This is worrying, because according to the industry association VDA, three out of four cars produced in Germany in 2023 were delivered abroad. German car production has fallen by 25 percent since 2018, exacerbating the economic situation for many suppliers. 1

- High competitive pressure and OEM requirements: Original equipment manufacturers (OEMs) - in the automotive sector either the vehicle manufacturers themselves or their direct system partners - demand maximum flexibility and availability from suppliers in the downstream supply chain. Orders must be processed in the shortest possible time, which requires agile and efficient production.

- Short-term decisions: Due to high competitive pressure, quick decisions and short delivery times are essential. This presents companies with logistical and organizational challenges.

- Working environment and efficiency: Working in metal processing can often be strenuous and monotonous. Fewer and fewer people are willing to do such work. At the same time, margins are low, making it difficult to invest in new technologies to mitigate the shortage of skilled workers.

Solutions through robotic automation

Many companies have been relying on automation for some time now. However, this is often only rudimentary or at an outdated technological level. The potential for optimization is correspondingly high. Robot-assisted automation can be used in a targeted manner to meet current challenges.

- Flexibility and increased efficiency: Modern robot solutions enable rapid adaptation to changing production requirements. They are incomparably more flexible than conventional industrial robots from earlier years, as they can be set up, programmed and retooled much more quickly and easily. As a result, this leads to a more efficient and faster start to automated production.

- Integration of peripheral devices: Another factor in the rapid switch to automated production is the use of seamless interfaces: For a variety of tasks in metal processing, for example machine loading or part separation, there are standardized complete solutions in which robots are combined with the devices and tools required for the respective application. This ensures communication between all components involved in the automation - which in turn greatly reduces the risk of system failure and leads to high-quality results.

- Improving working conditions: When robots take over simpler and/or monotonous tasks - ideally autonomously for as long as possible without human intervention - a company can firstly save on personnel costs. In addition, production can be maintained or even expanded, even if there is a shortage of personnel. Last but not least, qualified specialists can be deployed for other, more demanding tasks.

- Cost efficiency after initial investment: Although the implementation of automation solutions requires the willingness to make an initial investment, this pays for itself through increased efficiency and reduced error rates. What many companies are not yet aware of is that the threshold for making a profit is no longer a question of years; innovative solutions generally pay for themselves after just a few months. Companies with a high willingness to invest can thus secure their long-term competitiveness.

- Rapid implementation: Modular automation solutions enable rapid integration into existing production lines. This is particularly important in order to meet the requirements of the next companies up the supply chain for short delivery times.

Practical examples of automation solutions

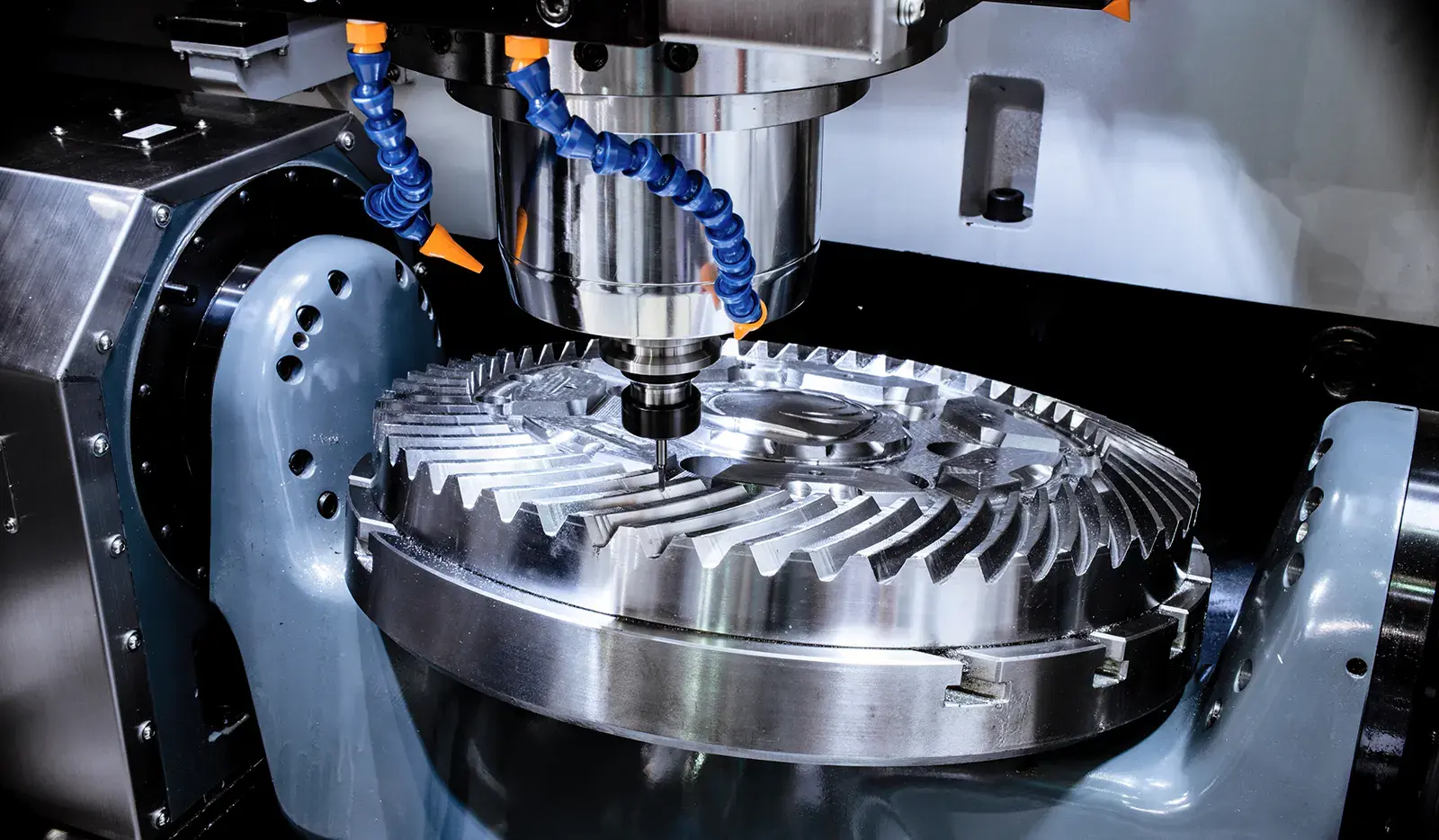

- Machine loading: The use of robots for automatic loading and unloading of CNC machines increases efficiency and precision. The entire process can be optimized through the simple and flexible integration of different grippers and suitable clamping technology.

- Parts feeding and removal: Automated systems with camera integration and conveyor technology enable precise and fast feeding of components. This is an important step for subsequent production processes such as assembly, quality control or machine loading. Automation reduces manual intervention and increases productivity. It is important to ensure that the chosen solution can interact ideally with the workpieces.

Conclusion

Conclusion

The automotive supply industry is facing considerable challenges due to technological change and economic uncertainties. Robot-assisted automation offers concrete solutions to increase flexibility, efficiency and quality in production. Companies that are prepared to invest in modern technologies can secure their competitiveness and emerge stronger from the change.

Sources