Case Studies and references with HORST: Success stories of our customers

Discover how companies can increase the productivity and availability of their use cases thanks to intelligent Digital Robots. Find out how your employees can be relieved of monotonous and repetitive tasks.

Case Studies

You can learn about the advantages of using intelligent industrial robots in many applications, such as parts handling or pick-and-place use, by reading the success stories of our customers.

Set up your Digital Robot now

Put together your own intelligent automation solution with just a few clicks.

1

Which Digital Robot HORST will suit your use case best?

2

Which software features will give you a competitive edge?

3

How do you secure the best lifecycle costs through additional services?

HORST in practical use: references from our customers

Hundreds of Digital Robots are already in daily use in various sectors of industry. Watch these videos to see some examples of how our customers sustainably increase their productivity, quality and efficiency thanks to automation with HORST.

Digital Robot HORST mit Be- und Entladungsaufgaben in der Qualitätssicherungszelle von Lenkering an Spritzgussmaschinen

Digital Robot HORST mit Be- und Entladungsaufgaben in der Qualitätssicherungszelle von Lenkering an Spritzgussmaschinen

Let yourself be convinced by the assessment of other HORST users

We use the test cell for technological feasibility analyses and innovations in product development and are thrilled. The Solution Kit can be put into operation, programmed and operated quickly and easily without any special prior knowledge.

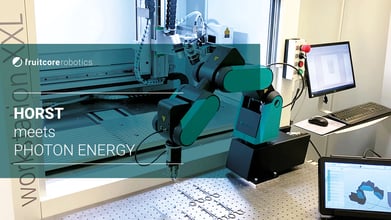

With HORST, we are very well positioned in our test lab. The compact footprint is very convenient and the usability of the robot is a great advantage, especially for the complex test setups.

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

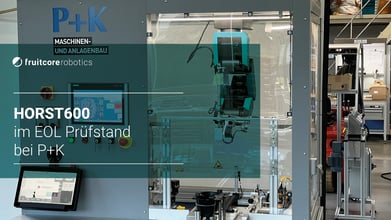

The high quality demands placed on our products require first-class quality assurance. By using the HORST industrial robot, we have not only created the best testing conditions, but also significantly increased product quality. The robot has relieved our employees of monotonous tasks as well as led to an increase in productivity and a high level of satisfaction among our customers.

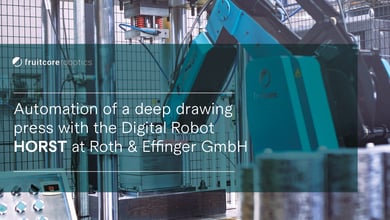

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

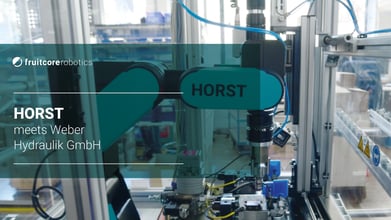

HORST takes over typical pick & place tasks for us during a hydraulic test and enables a fully automated testing process. As a result, we achieve a significantly higher output and increase our productivity. We were also convinced by the easy operation of the industrial robot, the good price and the comprehensive support from fruitcore.

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

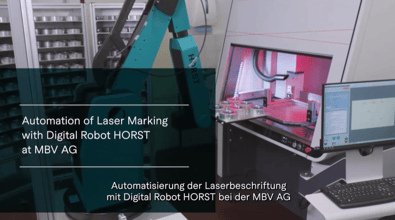

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Your contact to fruitcore robotics

Do you have further questions about our unique automation solutions or already have a specific application in mind that you would like to automate and optimize with us? Do not hesitate to contact us. We look forward to discussing your individual needs and developing innovative solutions for your company together.