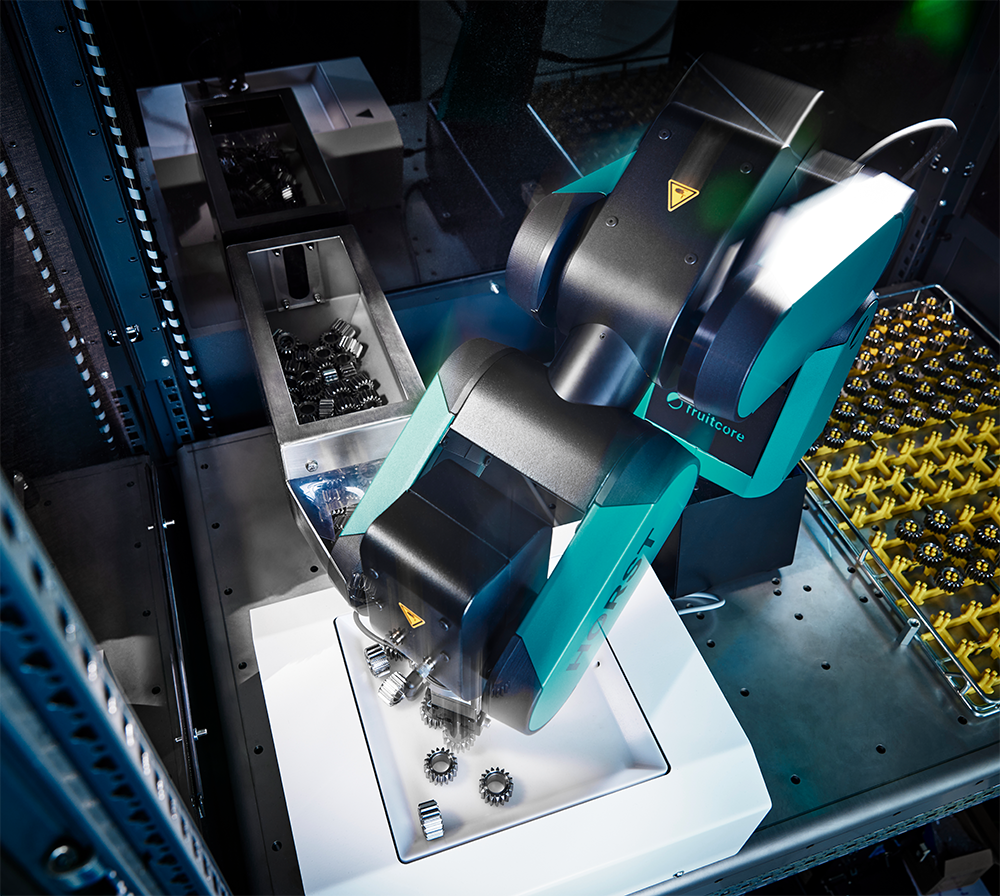

Efficient separation made easy: HORST sorts your bulk material

With our Digital Robots, you achieve an extremely high repeatability of ±0.05mm and precisely separate your components. Let HORST do the work and devote yourself to the important things in life. Sorting bulk material has never been so easy.

Optimize your processes with HORST and increase your efficiency in parts separation

In this section, we present specific advantages of HORST for tasks in the area of separation - for example, in the sorting of small parts or in the provision and feeding of material for machines. Find out how intelligent automation applications can help you move your business forward in a targeted way.

Bring order to the sorting of your parts thanks to seamless robot integration

Digital robots can be integrated into all peripheral devices: If HORST acts with a camera, for example, it receives a sense of sight and recognizes the position of components precisely. Thanks to the enormously flexible kinematics over 6 axes, it effortlessly reaches different gripping positions.

Increase your productivity dramatically and avoid production errors

Thanks to the extremely high repeatability of ±0.05mm, you sort parts precisely into the correct position in your workpiece carrier. Prepare your raw material optimally for all subsequent processes with our automation Solution Kit Part Separation.

Achieve greater efficiency through automated separation

Stop wasting time with inefficient and manual processes in your production. The intelligent Digital Robot HORST enables faster and continuous feeding of bulk material without the need for constant manual intervention.

Get the best ROI for singulation application automation

By using your resources more efficiently and reducing manual tasks, using a HORST actively lowers your ongoing operating costs, ensuring you a quick return on investment - often in as little as 6 months.

From now on avoid bottlenecks and downtime of your production

With HORST, you can not only run your application 24/7. Through smart connectivity, our Digital Robot enables predictive maintenance or program optimization. This effectively reduces downtime and maintenance costs.

Adapt flexibly and quickly to unexpected changing tasks with HORST

We know how important it is to be able to adapt immediately to surprising market changes. That's precisely why our intelligent industrial robots are designed to meet a wide range of requirements.

Successful with HORST: Let our customers convince you

We use the test cell for technological feasibility analyses and innovations in product development and are thrilled. The Solution Kit can be put into operation, programmed and operated quickly and easily without any special prior knowledge.

With HORST, we are very well positioned in our test lab. The compact footprint is very convenient and the usability of the robot is a great advantage, especially for the complex test setups.

We are more than satisfied with HORST as well as with the service and support from fruitcore robotics. The team is extremely competent, friendly and very helpful. The optimal solution for us!

The high quality demands placed on our products require first-class quality assurance. By using the HORST industrial robot, we have not only created the best testing conditions, but also significantly increased product quality. The robot has relieved our employees of monotonous tasks as well as led to an increase in productivity and a high level of satisfaction among our customers.

With HORST, we have achieved a very large increase in efficiency. We now produce twice as many parts and have thus been able to significantly increase our sales. The robot had already paid for itself after the first series.

HORST takes over typical pick & place tasks for us during a hydraulic test and enables a fully automated testing process. As a result, we achieve a significantly higher output and increase our productivity. We were also convinced by the easy operation of the industrial robot, the good price and the comprehensive support from fruitcore.

The implementation of this automation task worked quickly. Just like the cooperation with fruitcore robotics has always worked great.

The automation of laser marking with HORST enables us to mark many thousands of perforated lids per year with a unique code. The automation helps us to increase quality while staying flexible for different customer needs.The system is exactly what we needed.

Sort quickly and efficiently: Revolutionize your parts separation with HORST too

Watch the video to see how our Solution Kit Part Separation, a complete solution for your application, sorts bulk material at lightning speed. The combination of HORST with our flexible robot platform and components assembled according to your needs enables quick and easy project planning and processing. Processes can be mapped with the Solution Kit Part Separation without any additional PLC. Just see for yourself how you can make part separation child's play!

Do you have questions about parts separation with HORST? Contact us directly!

Want to learn more about how our intelligent digital robots can help you sort parts or feed materials, for example? Contact our robotics experts and together we can find a solution to your separation challenges.